I. Overview of Titanium Fuel Bipolar Plate

Titanium-fueled bipolar plate is a key component that plays the role of current collection and conduction in the fuel cell, and also serves as a gas flow channel to prevent hydrogen and oxygen from mixing. Titanium-fueled bipolar plates are an important component in fuel cells, and their performance directly affects the efficiency and stability of fuel cells. Due to its unique structure and function, titanium fuel bipolar plate has a wide range of application prospects in the field of fuel cells.

II. Main functions of titanium fuel bipolar plate

1. Current collection and conduction: Titanium fuel bipolar plate acts as the current path in the fuel cell to collect and conduct the current generated by the reaction of hydrogen and oxygen. Therefore, the bipolar plate needs to have good electrical conductivity and stable physicochemical properties.

2. Gas flow path: As the gas flow path in the fuel cell, titanium fuel bipolar plate needs to ensure that hydrogen and oxygen can flow to the cathode and anode of the cell respectively. Therefore, titanium fuel bipolar plates need to have precise geometry and size to realize efficient gas flow.

3. Prevent gas mixing: In order to ensure the safe operation of the fuel cell, titanium fuel bipolar plates need to prevent hydrogen and oxygen from mixing. Therefore, titanium fuel bipolar plates need to have reliable sealing performance.

III. the bipolar plate etching process and stamping process and other technology comparison

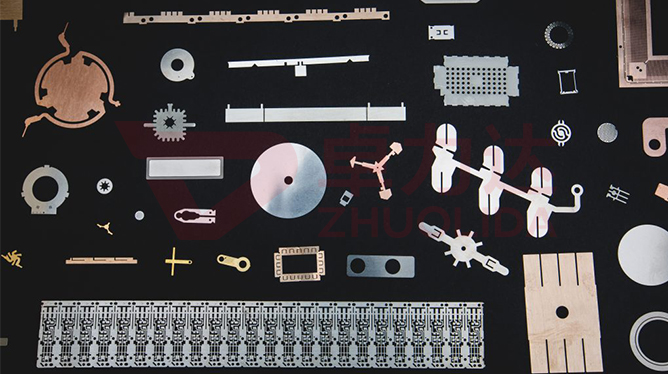

There are various processes for manufacturing titanium fuel bipolar plates, including mechanical processing, electrochemical processing, laser processing and so on. Among them, the bipolar plate etching process has the advantages of high precision, high efficiency, high reliability and versatility, and is widely used in the manufacture of titanium fuel bipolar plate.

1. Mechanical processing: Mechanical processing is a traditional manufacturing process with the advantages of high processing efficiency and low cost. However, machining is difficult to realize the processing of complex shapes and sizes, and the surface quality is difficult to ensure. Therefore, machining is not suitable for the manufacture of titanium fuel bipolar plates.

2. Electrochemical machining: electrochemical machining is a manufacturing process based on electrochemical reaction, which can process parts with high precision and high surface quality. However, the efficiency of electrochemical machining is low and it is difficult to realize large area machining. Therefore, electrochemical machining is also not suitable for the manufacture of titanium fuel bipolar plates.

3. Laser processing: Laser processing is a high-precision, high-efficiency manufacturing process that can produce high-quality parts. However, the cost of laser processing is high and it is difficult to realize large area processing. Therefore, laser processing is also not suitable for the manufacture of titanium fuel bipolar plates.

In contrast, bipolar plate etching processing has the following advantages:

1. High precision: bipolar plate etching processing can realize high-precision processing by accurately controlling the concentration and temperature of the etching solution, etching time and etching depth and other parameters. In addition, the etching process can also realize the processing of complex shapes and sizes through mask technology.

2. High efficiency: bipolar plate etching processing can realize high-efficiency production on large-area metal surfaces, thus improving production efficiency and reducing production costs.

3. High reliability: Bipolar plate etching processing can realize reliable metal removal and surface treatment by controlling parameters such as composition and concentration of corrosive solution, thus improving the reliability and stability of products.

4. Multifunctionality: Bipolar plate etching processing can realize a variety of materials and functions through different etching solution and surface treatment technology. For example, different materials such as titanium alloy, coating and composite materials can be used as raw materials to realize the manufacture of bipolar plates with different properties.

IV. Conclusion

Titanium-fueled bipolar plates are one of the important components in fuel cells, and the choice of their manufacturing process directly affects the performance and quality of the product. Compared with other processes, bipolar plate etching processing has the advantages of high precision, high efficiency, high reliability and versatility, which is suitable for the manufacture of titanium fuel bipolar plates. In the future, with the continuous development of fuel cell technology, bipolar plate etching will play an increasingly important role in the manufacture of titanium fuel bipolar plates.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China