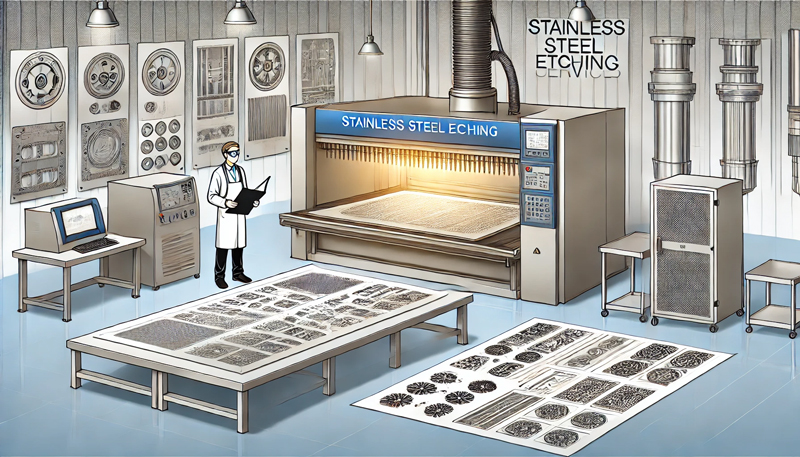

Stainless steel etching manufacturers usually have rich experience in metal processing and advanced etching technology, and are able to provide high-precision patterns and customized services. Below are some typical types of stainless steel etching manufacturers, and their service characteristics:

Specialized Etching Manufacturers Manufacturers specializing in the field of etching are good at providing stainless steel etching services for complex patterns and precision structures. These types of manufacturers tend to have high-end equipment and are suitable for industries with high demands for quality and detail, such as electronics, automotive, medical and aerospace.

Printed Circuit Board (PCB) Manufacturers PCB manufacturers typically offer micron-level etching technology, and stainless steel etching is more prevalent in applications such as electronic components and sensors. These manufacturers can often achieve high density patterns suitable for complex circuits and sensing devices.

Precision Metal FabricatorsThese fabricators offer precision etching services for stainless steel and other metal materials, covering small pilot quantities to high volume production. Their etching processes are typically applied to precision filters, optical components, medical devices, and other products that require high levels of accuracy and repeatability.

Architectural and Decorative Materials Factory Some manufacturers offer decorative etching services designed for architectural décor, signs, nameplates, and more. Their etching process can be customized with a variety of patterns for highly decorative stainless steel products.

Microfabrication Laboratory or R&D ManufacturersThese manufacturers mainly provide etching services for small quantities, irregular shapes or special patterns, which are suitable for product development and pre-testing to help customers develop new processes and optimize designs.

When selecting a stainless steel etching manufacturer, it is recommended to evaluate their equipment capabilities, process accuracy, and batch production capacity based on project needs.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China