metal etching process is an ancient and fine metal processing technology. Through chemical or physical treatment on the metal surface, various patterns, characters or textures are formed, which adds unique artistry and decoration to metal products. This technology is widely used in architecture, jewelry, art and other fields, which brings colorful visual experience to our life.

一、the history and characteristics of metal etching process

The history of metal etching process can be traced back to ancient times, when people used acidic solution to etch patterns and characters on the metal surface for decoration and logo. With the development of science and technology, metal etching process has gradually evolved into a highly sophisticated art form, which combines knowledge and technology in many fields such as chemistry, physics and art design.

The characteristic of metal etching process is that uneven patterns and characters can be formed on the metal surface, which has a strong three-dimensional sense and touch. This process can accurately control the depth and shape of corrosion, thus making various fine patterns and textures. In addition, metal etching also has the advantages of wear resistance and not easy to fade, so that the products can maintain their aesthetics and decoration for a long time.

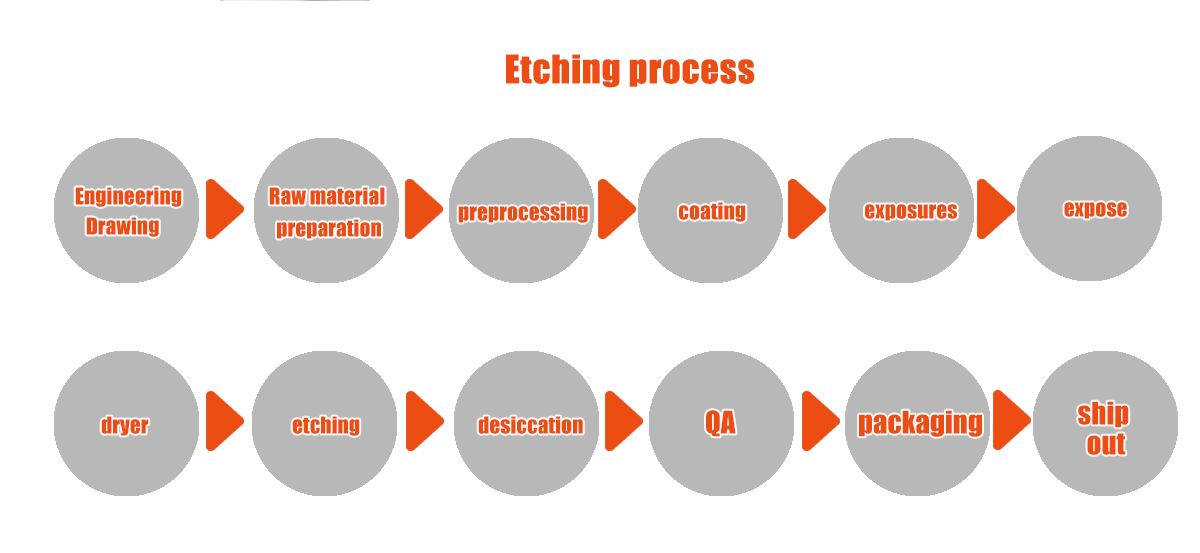

二、 the operation process of metal etching process

Design stage: design patterns or characters to be etched according to requirements, which can be completed by using computer-aided design software.

Material preparation: select the appropriate metal material and etching solution. Different metal materials have different reactions to the etching solution, so it is necessary to choose a suitable etching solution to obtain an ideal etching effect.

Metal treatment: Clean and pretreat the metal surface to remove oil stains, impurities and oxides on the surface, so as to obtain a smooth and clean surface.

Coating a resist layer: coating a resist layer on the surface of the metal to be preserved to protect this part of the metal from the influence of the etching solution.

Etching treatment: Immerse the metal in the etching solution, and control the factors such as time, temperature and concentration of the etching solution, so that the etching solution can corrode the metal surface and form the required patterns or characters. This step requires precise control of various parameters to obtain ideal etching effect.

Post-treatment: after the etching is completed, the etching solution and residue on the surface are washed away and then dried. Post-treatment processes such as grinding, polishing or coloring are carried out as needed to improve the gloss and smoothness of the products.

三、 the application field of metal etching process

Architectural field: metal etching technology is widely used in the surface decoration of building doors and windows, curtain walls, railings, etc., which can enhance the artistic and cultural atmosphere of the building.

Jewelry field: metal etching process can be used to make various jewelry, such as rings, necklaces, earrings, etc. By etching unique textures and patterns, the personality and value of jewelry can be displayed.

Art field: metal etching technology can be used to make various works of art, such as sculptures and murals, and to show the artist's creative style and ideological connotation by etching complex patterns and characters.

Industrial field: Metal etching process can also be applied to industrial field, such as making metal parts of mechanical equipment, electronic products, etc. By etching marks and information, the recognition and quality of products can be improved.

四、the development trend and challenges of metal etching process

With the continuous progress of science and technology and the continuous expansion of application fields, the metal etching process is also constantly developing and improving. In the future, the process will develop in a more efficient, environmentally friendly and beautiful direction. However, there are also some challenges, such as how to improve the etching speed and quality, reduce the production cost, and deal with the restrictions of environmental laws and regulations. Therefore, it is necessary to continuously carry out technological innovation and research and development to meet the market demand and environmental protection requirements.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China