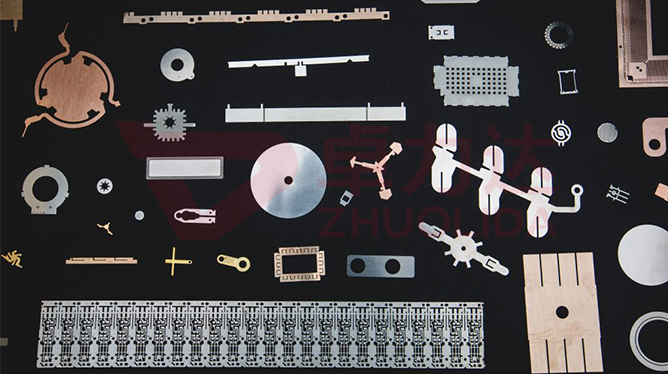

Stainless steel mask plate etching processing is a precision manufacturing technology, widely used in microelectronics, nanotechnology, optoelectronics and other fields. In this paper, we will introduce the etching process of stainless steel mask plate in detail, including the material selection of mask plate, surface treatment, etching process, quality inspection and other aspects.

First, material selection

Stainless steel mask plate commonly used materials include stainless steel 304, 316, etc. These materials have excellent corrosion resistance and mechanical properties, and can meet a variety of high-precision processing requirements. When selecting the material, it should be selected according to the actual application scenarios and processing requirements to ensure processing quality and reliability.

Second, surface treatment

The surface treatment of stainless steel mask plate is one of the key steps in etching processing, the purpose of which is to improve the surface flatness and adhesion of the mask plate, in order to facilitate the subsequent etching process. Surface treatment mainly includes polishing, etching, coating and other steps.

1. Polishing: through mechanical polishing or chemical polishing methods, to remove scratches, burrs and other defects on the surface of the mask plate, to improve the surface flatness.

2. Etching: the use of chemical etching agent on the surface of the mask plate corrosion treatment to obtain the desired pattern and shape. The choice of etchant should be based on the type of material and processing requirements.

3. Coating: Cover the mask plate surface with a thin film to improve its corrosion resistance and wear resistance. Commonly used coating materials are chromium, nickel and so on.

Third, etching process

Etching process is the core link of stainless steel mask plate etching process, mainly including dry etching and wet etching two methods.

1. Dry etching: the use of plasma or high-energy particles on the surface of the mask plate for etching, has the advantages of fast etching speed, high precision. Dry etching equipment commonly used reactive ion etching machine, plasma etching machine.

2. Wet etching: the use of chemical solutions on the mask plate surface corrosion, has the advantages of simple operation, low cost. Wet etching commonly used chemical solutions are nitric acid, hydrochloric acid (this word is a chemical word, I can not identify), hydrofluoric acid and so on.

When choosing the etching method, it should be selected according to the processing requirements and the type of material. For high-precision processing, dry etching is generally used; for mass production or simple shape processing, wet etching is more advantageous.

Fourth, quality testing

Quality inspection is to ensure the quality of stainless steel mask plate etching process an important link, mainly including the appearance of the test, size detection and performance testing and other aspects.

1. Appearance inspection: check the surface flatness of the mask plate, there are no scratches, burrs and other defects. Generally visual or optical microscope detection.

2. Dimensional inspection: Measure the geometric dimensions of the mask plate, such as thickness, width, length and so on. Generally use precise measuring instruments for testing.

3. Performance testing: Test the physical and chemical properties of the mask plate, such as hardness, tensile strength, corrosion resistance and so on. Generally use professional testing equipment for testing.

V. Summary

Stainless steel mask plate etching processing is a high-precision manufacturing technology, widely used in microelectronics, nanotechnology, optoelectronics and other fields. Stainless steel mask plate material selection, surface treatment, etching process and quality testing. In practical application, it should be selected and optimized according to the processing requirements and material type to ensure processing quality and reliability. With the continuous progress of science and technology, stainless steel mask plate etching processing technology will continue to develop and improve, providing better support for innovation and development in various fields.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China