New energy fuel cell stack electrolyzer is an important part of the fuel cell system, and its main role is to provide hydrogen and oxygen, and generate electrical energy. The electrolyzer consists of several electrolysis units, each of which includes an anode, cathode and bipolar plates.

The main function of the anode is to provide hydrogen and generate electrical energy. In fuel cell stacks, anodes are usually made of metal materials such as stainless steel and titanium. In order to improve the conductivity and corrosion resistance of the anode, the metal surface is usually coated with a layer of catalyst, such as platinum, palladium and other precious metals.

The main function of the cathode is to provide oxygen and generate electrical energy. In fuel cell stacks, the cathode is usually made of metal materials, such as stainless steel and titanium. In order to improve the conductivity and corrosion resistance of the cathode, the metal surface is usually coated with a layer of catalyst, such as oxides and nitrides.

The metal bipolar plate is another important part of the electrolyzer, which is located between the anode and cathode and serves to separate hydrogen and oxygen and collects the current. Metal bipolar plates are usually made of highly conductive materials such as graphite and carbon fiber.

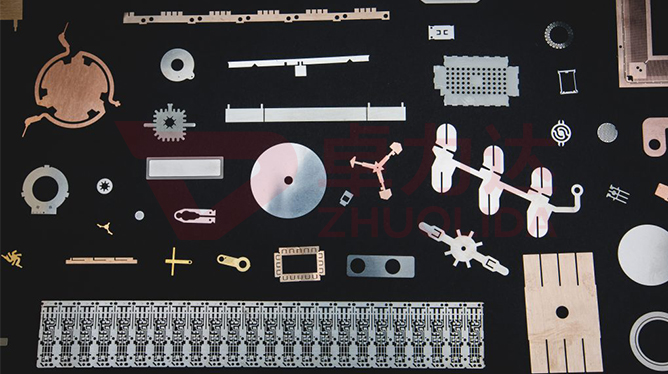

Metal bipolar plate etching is a common process in the production of electrolyzer. Metal bipolar plate etching can precisely machine the shape and size of the electrolyzer while improving surface roughness and accuracy. The principle of Bipolar Plate Etching is that the electrolytic bath is immersed in an etching solution, which gradually dissolves the surface material through a chemical reaction. Metal bipolar plate etching processing can be used to process anode, cathode and bipolar plate and other components.

In a nutshell, the main role of the electrolyzer of new energy fuel cell stack is to provide hydrogen and oxygen and produce electricity. In the production process, metal bipolar plate etching is a commonly used process to precisely machine the shape and size of the electrolyzer and to improve the surface roughness and accuracy.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China