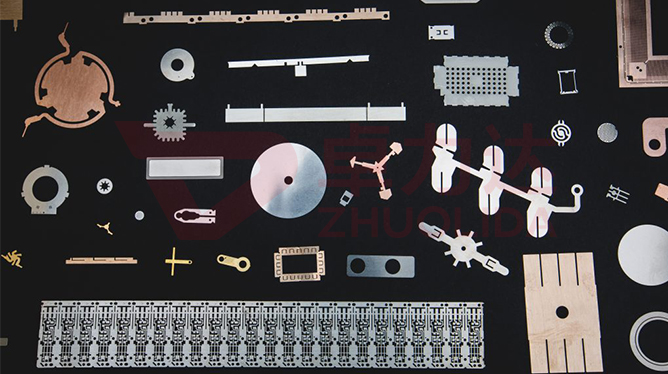

Stainless steel metal sheet etching processing is a commonly used manufacturing method, which can be used to make a variety of microfabricated and high-precision parts. The following is the whole process of its processing:

1, prepare the workpiece and material

Before etching processing, you need to prepare stainless steel metal sheet, resist, etching solution and other materials and tools. Stainless steel metal sheet can be flat or curved, according to the need to choose. The type and concentration of resist and etching solution will also vary depending on the processing requirements and materials.

2, coating resist

Clean the surface of the stainless steel metal sheet, and then coat a layer of resist. The role of the resist is to protect the parts that do not need to be etched to prevent the etching solution from causing damage to them. The resist can be a colloidal or thin film, depending on the need. When coating the resist, make sure it is evenly distributed to avoid bubbles or peeling.

3, exposure

The stainless steel metal sheet coated with resist is placed in an exposure machine, and the resist under the mask is polymerized and reacted by ultraviolet light or electron beam irradiation. The mask is a film with a pattern that protects the part that does not need to be etched. The exposure process needs to be adjusted according to the desired pattern and accuracy of the exposure time and the intensity of the light source.

4, developing

The exposed stainless steel metal sheet is put into the developing solution, the unpolymerized resist will be gradually washed away, while the polymerized resist is retained on the surface of the metal sheet. The type and concentration of the developer will also vary depending on the resist. The developing process requires time and temperature control to ensure the integrity and precision of the pattern.

5. Etching

The stainless steel metal sheet that has finished developing is put into the etching machine, and the metal part under the protection of the resist will be gradually corroded through the action of the etching solution. The type and concentration of etching solution will also vary depending on the material. Factors such as temperature, etching time and concentration of etching solution need to be controlled during the etching process to ensure the quality and precision of the final product.

6, debinding

After the etching is completed, the resist remaining on the surface of the metal sheet is removed. This step is usually completed using organic solvents or heating and other methods. In the process of removing the adhesive need to control the time and temperature and other factors to ensure that the removal of clean and will not cause damage to the metal sheet.

7, cleaning and inspection

Degumming completed stainless steel sheet metal for cleaning to remove surface impurities and residues. Then check, if there is a need to correct the place, you can again etching or photolithography operation. Finally, quality inspection to ensure that the precision and quality of the product meets the requirements.

8, end

After completing all the checks and corrections, the stainless steel metal sheet etching process is over. This process can get high-precision microfabrication, laying a good foundation for subsequent applications. At the end of the stage needs to be organized and archived materials, while the waste liquid and waste are properly disposed of.

In short, stainless steel metal sheet etching processing is a fine and complex process, requiring a high level of technical level and strict process control to obtain high-quality products. In the actual production need to pay attention to the impact of various factors, such as the choice of materials, resist and etching solution preparation and use, temperature and time control. Only by doing a good job in every aspect can the quality and precision of the final product be guaranteed.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China