Precision dustproof mesh corrosion processing is a special processing technology mainly used to manufacture mesh with specific dustproof performance. This processing technology involves many fields, including material science, mechanical engineering, chemical engineering and so on. The following will introduce the various aspects of precision dustproof mesh corrosion processing in detail.

First, the definition of precision dustproof mesh corrosion processing

Precision dustproof mesh corrosion processing is a kind of chemical or electrochemical methods of corrosion processing of metal materials, in order to manufacture mesh with specific dustproof performance technology. This processing technology can change the surface morphology and structure of the metal material, so as to improve its dustproof performance.

Second, the principle of precision dustproof mesh corrosion processing

Precision dustproof mesh corrosion processing principle is the use of chemical or electrochemical reactions, so that the surface of the metal material atoms or ions dissolved or oxidized, thereby changing its surface morphology and structure. This processing technology can produce metal surfaces with micron or nano-scale structure, thus improving its dustproof performance.

Third, precision dustproof mesh corrosion processing methods

1. Chemical corrosion method

Chemical corrosion method is a commonly used precision dust mesh corrosion processing method. The method uses chemical reagents and the reaction of the surface of the metal material, so that its surface dissolution or oxidation. Commonly used chemical reagents include acids, alkalis, salts and so on. By adjusting the concentration of chemical reagents, temperature, time and other parameters, you can control the degree and shape of corrosion.

2. Electrochemical corrosion method

Electrochemical corrosion method is a method that utilizes the action of electric current to carry out corrosion processing of precision dustproof mesh. The method uses metal materials as anode, oxidation reaction occurs in the electrolyte solution, thus changing its surface morphology and structure. By adjusting the size of the current, the voltage level, the type of electrolyte and other parameters, you can control the degree and shape of corrosion.

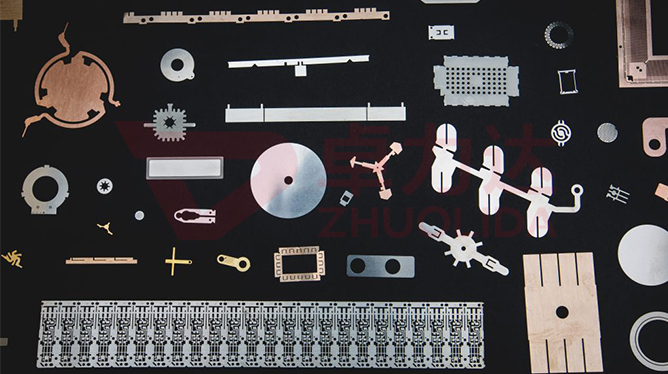

Fourth, the application of precision dustproof mesh corrosion processing

Precision dustproof mesh corrosion processing has a wide range of applications in many fields, including aerospace, automobile manufacturing, electronics industry, environmental protection projects. The following are a few specific application examples:

1. Aerospace field: precision dust-proof mesh can be used to manufacture air intakes and engine parts of airplanes and rockets to prevent dust and impurities from entering and improve the performance and life of the engine.

2. Automobile manufacturing field: Precision dustproof mesh can be used to manufacture the intake system and fuel system of automobile engines to prevent dust and impurities from entering and improve the performance and life of the engine.

3. Electronic industry: Precision dustproof mesh can be used to manufacture electronic components and integrated circuits packaging materials to prevent dust and impurities from entering and improve product reliability and stability.

4. Environmental protection engineering field: precision dustproof mesh can be used to manufacture environmental protection equipment filtration materials to prevent dust and impurities from entering, improve the filtration efficiency and stability of the equipment.

V. The advantages and limitations of precision dustproof mesh corrosion processing

1. Advantages:

(1) It is possible to create a metal surface with micron or nanometer structure, thus improving its dustproof performance;

(2) The degree and shape of corrosion can be controlled by adjusting the parameters of chemical reagents or electric current;

(3) It can be applied in many fields and has a wide range of application prospects.

2. Limitations:

(1) For some metal materials, there may be problems of slow corrosion rate or difficult to control;

(2) For some application scenarios, higher precision and more complex processing may be required;

(3) For some application scenarios, there may be higher costs.

Sixth, the future development trend

With the continuous development of science and technology, precision dust mesh corrosion processing technology is also progressing and improving. Future development trends include:

1. Developing new chemical reagents and electrochemical methods to improve the corrosion rate and controllability;

2. Exploring new metal materials and processing techniques to improve product performance and stability;

3. Expanding new application areas and markets to promote the development and application of precision dustproof mesh corrosion processing technology.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China