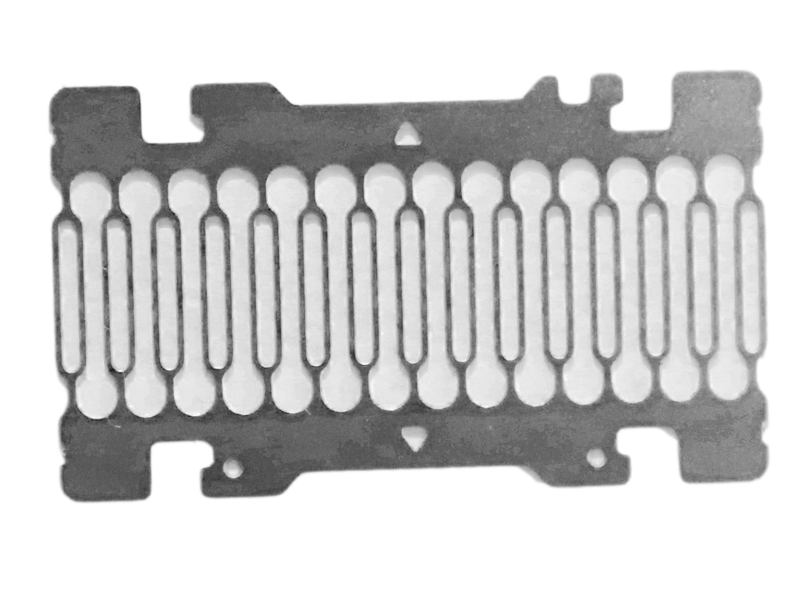

Razor mesh cover etching is a precision manufacturing process that aims to etch a specific pattern or text on the razor mesh cover to improve the aesthetics and experience of the product. This article will introduce the basic principles of razor mesh etching, process, equipment and safety precautions.

一、 the basic principle of razor mesh etching processing

Razor mesh cover etching process mainly utilizes the principle of chemical corrosion and electrochemical corrosion. By immersing the razor mesh in the corrosive solution, the corrosive solution and the chemical reaction of the metal material, resulting in dissolution and stripping effect, thus forming an uneven etching pattern on the metal surface. At the same time, by controlling the size of the voltage and current, you can adjust the depth and uniformity of the corrosion to obtain the desired etching effect.

二、 the process of razor mesh etching process

1. Preparation: check the material and specifications of the razor mesh, determine the required etching pattern or text, and develop a processing plan.

2. Pre-treatment: Clean and degrease the razor mesh cover to remove surface impurities and improve the etching effect.

3. Mask production: corrosion-resistant materials made of the same mask with the desired etching pattern or text, which will be affixed to the surface of the razor mesh.

4. Corrosion treatment: the mask will be affixed to the razor mesh immersed in the corrosion solution, adjust the voltage and current size, control the corrosion time and depth.

5. Post-treatment: Remove the mask, clean and dry the razor mesh to remove the residual corrosion solution and impurities.

6. Inspection and packaging: check whether the etching effect is in line with the requirements of the razor mesh for quality inspection, qualified products for packaging.

三、the razor mesh etching processing equipment

1. Etching solution preparation equipment: including etching solution tank, stirrer, meter and other equipment for the preparation of etching solution.

2. Power supply equipment: including DC power supply, AC power supply and other equipment, used to provide the required voltage and current.

3. Mask production equipment: including laser printer, cutting machine, embossing machine and other equipment, used to produce corrosion-resistant material mask.

4. Cleaning equipment: including water washing machine, ultrasonic cleaning machine and other equipment, used for cleaning the surface of razor mesh.

5. Testing equipment: including microscopes, measuring instruments and other equipment, used to check the etching effect and quality.

四、 safety precautions

1. Operators must be professionally trained, familiar with the process and equipment operation, and comply with safety regulations.

2. The etching liquid is strongly corrosive and irritating, the operator should wear protective glasses, masks, gloves and other personal protective equipment.

3. The equipment should be inspected and maintained regularly to ensure its normal operation and safety performance.

4. The waste gas and liquid generated in the process should be properly disposed of to minimize the harm to the environment and human body.

5. The operation site should be well ventilated to avoid prolonged exposure to corrosive liquids and other harmful substances.

6. If abnormal situation or safety accidents are found, the machine should be stopped immediately and reported to relevant departments or leaders for disposal.

In a word, razor mesh etching processing is a kind of fine manufacturing process, which requires operators to have professional skills and knowledge. Through reasonable process flow and correct operation method, it can improve the quality and aesthetics of the product, and at the same time protect the safety of the operator and the safety of the environment.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China