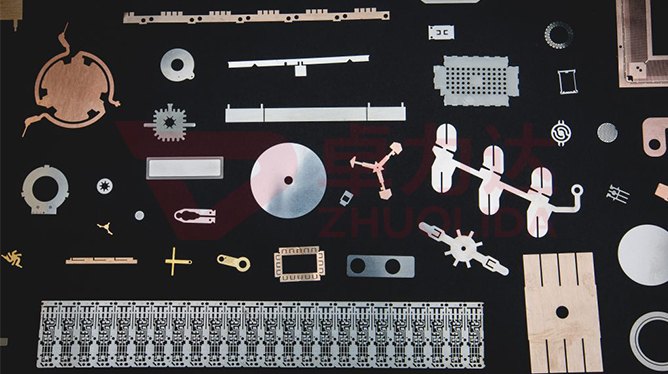

Ring gasket etching processing is a kind of process to realize precise and high-precision pattern or text on metal materials. The following is the main process of ring gasket etching processing:

1. Material Preparation: First, select appropriate metal materials, such as copper, aluminum, stainless steel and so on. These materials usually have high corrosion resistance and mechanical strength. Ensure that the surface of the material is clean and free of oil, oxides or other impurities.

2. Make the mask: Use a corrosion-resistant material, such as polyimide (PI) or polytetrafluoroethylene (PTFE for short), to make the mask. The mask should have a pattern opposite to the desired etching pattern. The purpose of this step is to protect the part that does not need to be etched.

3. Coating resist: Coat the resist on the metal surface to protect the part that does not need to be etched. The resist should have good adhesion and corrosion resistance.

4. Apply mask: Apply the made mask on the metal surface coated with resist, make sure that the mask fits tightly with the metal surface without bubbles or gaps.

5. Exposure: using ultraviolet light or electron beam light source, coated with a mask and resist metal surface exposure. The purpose of this step is to make the resist under the mask react chemically and become soluble.

6. Developing: The exposed metal surface is immersed in a developing solution to dissolve the exposed resist. The purpose of this step is to form the desired etching pattern.

7. Etching: The developed metal surface is put into the etching solution to etch the part that is not protected by the resist. Depending on the material selected and the etching solution, the etching process may take a certain amount of time and temperature.

8. De-masking: Peel the mask from the metal surface. Ensure that the mask is completely removed, leaving no residue.

9. Cleaning: Clean the metal surface with a suitable cleaning agent to remove residual resist and mask material. Ensure that the surface is clean and free of any impurities.

10. Quality check: Quality check the etched metal surface, including pattern integrity, precision and surface quality. Rework or adjust if necessary.

11. Post-treatment: According to the application requirements, the ring shims are post-treated, such as de-oxidized, polished, coated and so on. These treatments can improve the corrosion resistance, abrasion resistance and appearance quality of the ring gasket.

12. Packaging and Delivery: Packaging the completed ring shims to ensure that they are not damaged during transportation and storage. Finally, the ring shims will be delivered to customers or downstream processes for further processing or use.

Throughout the ring gasket etching process, each step needs to be strictly controlled to ensure the quality and precision of the final product. In addition, for different metal materials and etching requirements, the processing parameters and process flow may need to be adjusted. Therefore, in practice, it is recommended to develop detailed operating procedures and quality control measures according to the specific situation.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China