How to choose a Stainless steel etching processor? When choosing the right manufacturer, the following factors need to be considered:

1.Etching processing manufacturer processing quality: first of all, you need to examine the processing quality of the manufacturer. A quality stainless steel etching processing manufacturer should have exquisite processing technology, be able to accurately execute the order requirements, and provide customers with high-quality products. You can judge the processing quality by viewing the manufacturer's samples or actual products.

2. Etching processing manufacturer production capacity: when choosing a stainless steel etching processing manufacturer, you need to consider its production capacity. The production capacity of the manufacturer should be able to meet the demand of your order and be able to complete it within the specified time. Otherwise, it may cause delays in orders and affect your overall program.

3. Etching processor equipment and technology: the advanced level of equipment and technology used by the manufacturer is also one of the factors for selection. Advanced equipment and etching technology can improve production efficiency and can ensure the precision and quality of products. Therefore, when choosing a manufacturer, you need to understand the status of the equipment and technology it uses.

4. Price of the etching processor: When choosing a stainless steel etching processor, price is also an important consideration. Prices may vary from one manufacturer to another and need to be chosen according to your budget and needs. When choosing a manufacturer, you need to understand its price composition, whether it includes other costs and so on.

5. Etching processing manufacturer service and support: a quality stainless steel etching processing manufacturer should provide comprehensive service and support, including order tracking, technical support, after-sales service and so on. When choosing a manufacturer, you need to understand its service and support policy in order to get better protection in the subsequent cooperation.

6. Reputation and word of mouth: when choosing a stainless steel etching processing manufacturer, you need to consider its reputation and word of mouth. You can check the manufacturer's website, social media or other channels to understand its customer reviews and industry status. Choosing a manufacturer with a good reputation and word-of-mouth can ensure the safety and quality of your order.

7. Contract terms: After choosing a stainless steel etching processor, you need to sign a contract and finalize the order details. When signing the contract, you need to carefully read the terms of the contract to ensure that it meets your requirements and expectations. At the same time, you need to understand the breach of contract, confidentiality agreement and other important terms in the contract.

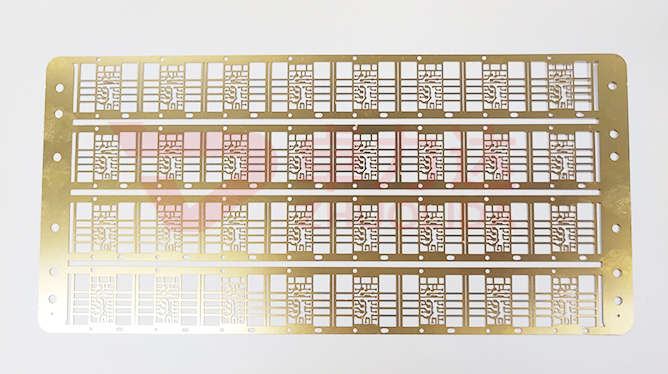

8. Sample or case demonstration: Ask the stainless steel etching processor to provide samples or case demonstrations in order to understand their actual experience and capabilities. By comparing the samples or cases of different manufacturers, you can better assess their processing quality and production capacity.

9. R&D and innovation ability: consider the R&D and innovation ability of stainless steel etching processing manufacturers. These factors can help manufacturers stay ahead of the competition and provide better quality products and services. Understanding whether the manufacturer has a R&D team, patented technology, etc. can provide you with more protection.

10. Communication and cooperation: When choosing a stainless steel etching manufacturer, you need to consider its communication and cooperation ability. Good communication can establish a good cooperative relationship and ensure that problems in the order process are solved in a timely manner. You can communicate with the manufacturer by phone, email or other means to understand its cooperative attitude and communication ability.

To summarize, there are several factors to consider when choosing the right stainless steel etching processing manufacturer. By carefully evaluating different manufacturers' processing quality, production capacity, equipment and technology, price, service and support, reputation and word-of-mouth, contract terms, samples or case presentations, R&D and innovation ability, and communication and cooperation ability can help you make the right decision. The manufacturer you ultimately choose should be able to meet your needs and expectations and provide high-quality products and services.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China