The advantages of stainless steel microporous mesh etching processing are mainly reflected in the following aspects:

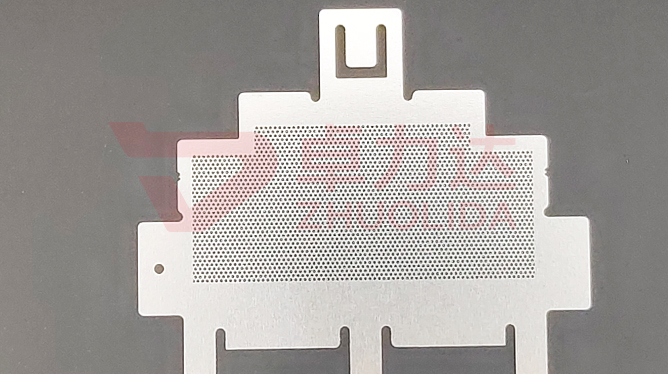

1. Fine and complex: Stainless steel microporous mesh etching technology can accurately manufacture complex stainless steel microporous mesh with fine structure and diverse shapes, providing a high degree of customization for various applications. This precision and complexity is important in many industrial applications, such as filtration, acoustics, vibration control, and decoration.

2. High efficiency: Stainless steel microporous mesh etching processing is a mass production method that can efficiently create large quantities of microporous mesh. Compared with traditional machining or drilling techniques, stainless steel microporous mesh etching can greatly improve production efficiency while ensuring accuracy.

3. Superior material: stainless steel is a common etching material, which has the characteristics of high strength, corrosion resistance, and beautiful appearance. This makes stainless steel microporous mesh etching products not only have excellent physical properties, but also exquisite appearance, long service life.

4. High flexibility: Stainless steel microporous mesh etching processing can make microporous holes on the surface of different materials, whether it is metal, plastic, or glass, ceramics, etc., which gives the designers a great deal of freedom to realize novel designs on a variety of materials.

5. Environmental protection: Stainless steel microporous mesh etching processing is a non-contact processing method, which does not generate cutting force or a large amount of cutting heat, so the processing does not generate a large amount of waste and heat, which has less impact on the environment.

6. Cost savings: Although the equipment for stainless steel microporous mesh etching processing has a large one-time investment, it can save a lot of manufacturing costs in the long run, taking into account its advantages of high efficiency, high precision and high quality.

7. Widely used: Stainless steel microporous mesh etching processed products are widely used in a variety of industries, such as petrochemical, food and medicine, aerospace, automobile manufacturing, electronic communications and so on. This makes stainless steel microporous mesh etching processing a technology with a wide range of applications.

8. High-precision control: Stainless steel microporous mesh etching processing can realize high-precision microporous manufacturing through precise control of chemical reactions and physical processes. This enables the production of microporous mesh with a high degree of consistency and repeatability, which is very important for products that require precise control.

Overall, the advantages of stainless steel microporous mesh etching process mainly lie in its fine complexity, high efficiency, superior material, high flexibility, environmental protection, cost saving, wide range of applications and high precision control. These advantages make stainless steel microporous mesh etching processing a highly competitive manufacturing method, providing high-quality and high-efficiency product solutions for a wide range of industries.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China