There are several main reasons for the etching and processing of high speed wind turbine mesh:

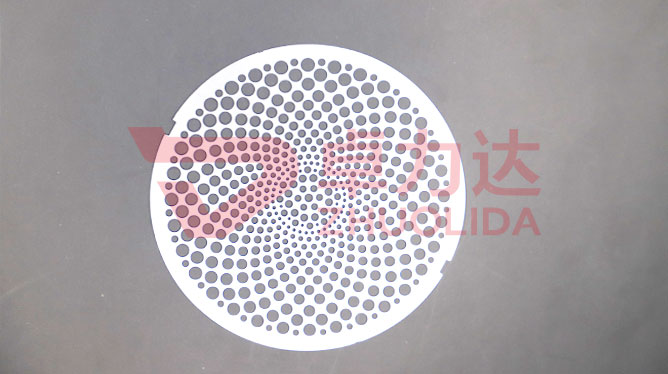

1. The precision of high-speed wind turbine mesh etching processing: high-speed wind turbine mesh needs to have high-precision holes and contours to realize precise airflow control. High-speed wind turbine mesh etching processing can process the metal surface into the required shape and size through precise chemical reaction, so as to meet the precision requirements of high-speed wind turbine mesh.

2. Uniformity of high-speed wind turbine mesh etching processing: high-speed wind turbine mesh etching processing can realize uniform corrosion effect on a large area of metal surface, so as to ensure that each hole on the high-speed wind turbine mesh has the same size and shape. This uniformity is very important for high-speed wind turbine mesh, because it can ensure the uniform distribution of airflow in all directions.

3. The high efficiency of high-speed wind turbine mesh etching processing: high-speed wind turbine mesh etching processing is a batch processing method, which can process multiple metal surfaces at the same time. This high efficiency makes the etching process in the production of high-speed wind turbine mesh with high productivity.

4. High-speed wind turbine mesh etching processing of environmental protection: high-speed wind turbine mesh etching processing is a wet chemical method, the use of chemical reagents such as acid or alkali. Compared with mechanical processing, etching processing produces less waste and pollution, more environmentally friendly.

5. Reliability of high-speed wind turbine mesh etching processing: During high-speed wind turbine mesh etching processing, the corrosion pits and contours on the metal surface are controlled by a chemical reaction, so it is more reliable. In contrast, machining methods may result in a decrease in processing accuracy due to tool wear, operational errors and other reasons.

6. The cost-effectiveness of high-speed blower mesh etching processing: Although high-speed blower mesh etching processing requires the use of chemical reagents and equipment, it is still very cost-effective. On the one hand, high-speed wind turbine mesh etching process can reduce the waste and reduce the subsequent processing steps (such as mechanical polishing), thereby reducing costs. On the other hand, high-speed blower screen etching processing can improve productivity, thus reducing the production cost per unit of product.

7. Adapt to different materials: high-speed wind turbine mesh etching processing can be applied to a variety of metal materials, including stainless steel, aluminum alloy, copper alloy and so on. This makes the etching process in the production of high-speed wind turbine net has a wide range of applications.

8. Easy to realize complex shapes: High-speed wind turbine nets are often required to have complex shapes and structures, such as three-dimensional holes and curved contours. Etching process can easily realize these complex shapes through the combination of multiple angles of corrosion, without the use of complex machining equipment or processes.

9. Improve product quality: High-speed wind turbine mesh etching process can realize high-precision holes and contour shapes by precisely controlling the chemical reaction conditions and etching time. This makes the product quality of high-speed wind turbine mesh improved significantly, thus improving its performance and service life.

10. Easy to realize automated production: with the development of automation technology, high-speed wind turbine mesh etching processing can be realized through automated equipment for continuous and efficient mass production. This not only improves production efficiency, but also reduces the cost of manual operation and error, and improves the consistency and stability of the product.

In summary, high-speed wind turbine net etching processing has significant advantages and application value in the production. It can meet the requirements of high-speed wind turbine net for high precision, high efficiency, environmental protection and other aspects, while adapting to the needs of different materials and complex shapes. Through the introduction of automation technology, high-speed wind turbine net etching processing can also realize efficient and continuous mass production, improve product quality and reduce production costs. Therefore, in the future field of high-speed wind turbine net manufacturing, high-speed wind turbine net etching processing will continue to play an important role.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China