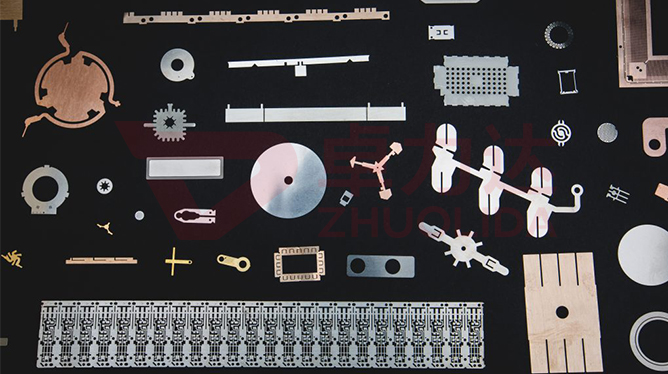

Filter mesh using etching processing and seamless welding process has many advantages, the following is a detailed description:

First, the advantages of etching processing

1. High precision: etching processing can accurately control the size and shape of the filter mesh to ensure the uniformity and consistency of the filter mesh. This accuracy makes the filter mesh can be better adapted to various application scenarios and improve the filtering effect.

2. Good surface quality: Etching process can get high quality surface, which makes the filter mesh have better abrasion resistance and corrosion resistance. This high-quality surface can improve the service life of the filter mesh and reduce the maintenance cost.

3. Diversified patterns and shapes: Etching process can easily realize a variety of complex patterns and shapes, which makes the design of filter mesh more flexible and diversified. This design flexibility can meet the needs of different customers and improve the market competitiveness of products.

Second, the advantages of seamless welding process

1. High connection strength: seamless welding process can realize the close connection between the filter mesh and improve the connection strength. This high-strength connection can ensure the stability and reliability of the filter mesh, avoiding problems such as air or water leakage in the process of use.

2. Good sealing: The seamless welding process can realize seamless connection between the filters and ensure the sealing of the connection. This sealing can prevent gas or liquid from leaking inside the filter mesh and improve the filtration effect.

3. High production efficiency: seamless welding process can realize automatic production and improve production efficiency. This efficient production method can shorten the production cycle, reduce production costs and improve the competitiveness of enterprises.

Third, environmental protection, energy saving advantages

1. Environmental protection: etching processing and seamless welding process in the production process produces less waste gas, waste water and waste, less impact on the environment. At the same time, these processes can also use environmentally friendly materials and processes to further reduce the impact on the environment.

2. Energy saving: In the production process, etching processing and seamless welding processes can use advanced energy-saving technologies and equipment to reduce energy consumption. Such energy-saving measures can reduce the operating costs of enterprises and improve economic efficiency.

Fourth, the summary

In summary, the use of etching processing and seamless welding process for roll-to-roll filter mesh has multiple advantages. These advantages include high accuracy, good surface quality, diverse patterns and shapes, high connection strength, good sealing, high production efficiency, as well as environmental protection and energy saving. These advantages make roll-to-roll filters have higher performance and use value in various application scenarios. Meanwhile, with the continuous progress and innovation of science and technology, these processes will continue to develop and improve, providing better solutions for the production and application of filter meshes.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China