In the process of titanium corrosion screen etching processing, it is necessary to follow a certain process flow and operational specifications to ensure processing quality and safety.

1. Introduction

Titanium is a lightweight, high-strength, corrosion-resistant metal material, which is widely used in aviation, medical, chemical and other fields. In some specific environments, such as marine engineering, hydrometallurgy and other industries, titanium materials need to withstand severe corrosion and abrasion, so special protective measures are required. Among them, titanium corrosion screens are a common protective component used to filter and block particles and impurities in corrosive media. This article will introduce the etching process of titanium corrosion screen.

2, the structure and material of titanium corrosion screen

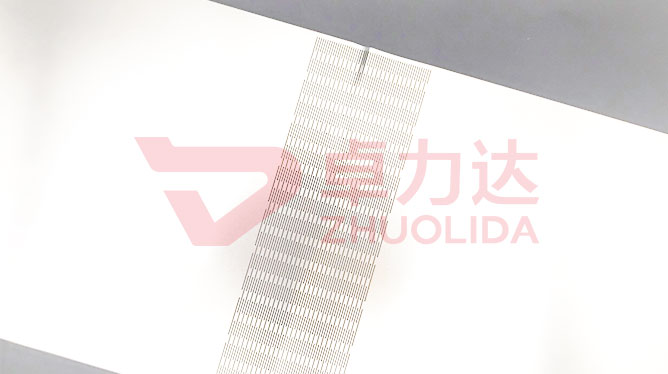

Titanium corrosion screen is usually made of titanium alloy, commonly used titanium alloys including Ti-6Al-4V, Ti-5Al-2.5Fe and Ti-0.2Pd. These alloys have a good combination of properties, including strength, hardness, corrosion resistance and machinability. The structure of titanium etching screen is usually mesh or honeycomb to increase the filtration area and strength.

3, the etching process flow

(1) Preparation: check whether the titanium corrosion screen blank to be etched meets the requirements, including material, size and surface quality. Prepare etching solution and cleaning solution to ensure that the quality and concentration of chemical reagents meet the requirements. Wear protective gear, such as gloves, glasses, masks and so on.

(2) Etching pre-treatment: pre-treatment of titanium etching screen blanks, including mechanical polishing, acid or alkali washing, etc., in order to remove surface dirt and oxidized layer and improve etching effect.

(3) Etching process: put the titanium corrosion screen blank into the etching solution, adjust the etching solution concentration, temperature and time and other parameters as needed. In the etching process, pay close attention to the etching progress, to prevent over-etching or under-etching phenomenon.

(4)Cleaning and film removal: After etching is completed, use the cleaning solution to clean the residue on the titanium etching screen, and remove the surface oxide film. Drying treatment after cleaning.

(5) Post-processing: post-processing of titanium corrosion screen, including orthopedic, inspection, packaging and so on.

4, the main points of operation and precautions

1. In the operation process, follow the safety regulations to ensure the safety of the staff.

2. Strict inspection of the titanium corrosion screen blank to be etched to ensure that the material, size and surface quality meet the requirements.

3. In the etching pretreatment process, select the appropriate polishing agent and pickling solution according to the material and surface quality. Polishing agent should be used in appropriate amount to avoid damage to the surface. The temperature and time of the pickling solution should be strictly controlled to prevent excessive corrosion.

4. In the etching process, the etching solution concentration, temperature and time and other parameters should be adjusted to ensure etching quality and efficiency. At the same time, we should pay close attention to the etching progress to prevent over-etching or under-etching phenomenon.

5. In the process of cleaning and de-filming, select the appropriate cleaning solution and de-filming agent, and strictly control the amount used. The temperature and time of the cleaning solution should be properly controlled, and the amount of film remover used should be appropriate to avoid damage to the surface.

6. In the post-treatment process, we should carry out operations such as straightening, inspection and packaging according to the requirements to ensure product quality and delivery time.

7. In the whole operation process, pay attention to environmental protection and resource utilization, reduce the emission of waste and pollutants.

V. Conclusion

Titanium corrosion Filter Etching Processing is an important metal processing technology, which is of great significance for improving the quality and performance of titanium alloy products. In the actual operation process, it is necessary to follow the safety operation procedures and process flow requirements, and strictly control the process parameters and quality standards to ensure product quality and safety. At the same time, it is necessary to strengthen the awareness of environmental protection and resource utilization, and reduce the emission of waste and pollutants.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China