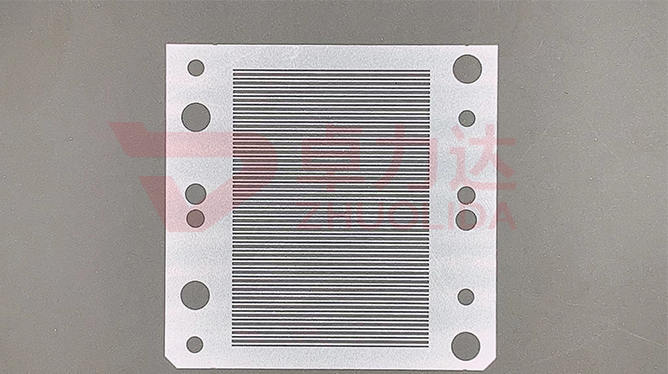

Precision gratings are very important components in optical instruments, which are used to generate accurate light distribution and light patterns. For such high-precision components, every aspect of the manufacturing process is critical. Between the etching process and stamping process, precision grating sheet etching process has some obvious advantages in manufacturing precision grating sheet.

1. Accuracy: Precision grating sheet etching process can significantly improve the angle accuracy and shape accuracy of the grating sheet. Since the chemical reaction used in the etching process can be precisely controlled, more accurate grating shapes and angles can be obtained. In contrast, stamping may affect the accuracy of the product due to wear and tear of the mold or differences in the nature of the material.

2. Material selection: Precision grating sheet etching processing can be applied to a variety of materials, including metal, silicon, glass and so on. This provides greater flexibility in the manufacture of lenticular lenses, allowing the use of materials better suited to the needs of a particular application. Stamping, on the other hand, has a relatively small range of material choices, depending primarily on the malleability and hardness of the material.

3. Productivity: Although precision lenticular sheet etching takes some time, the process can be massively parallelized. At the same time, due to no need for molds, precision grating sheet etching processing of the production cycle is also relatively short, more conducive to mass production. The productivity of stamping process is limited by the number of molds and life, mass production may be less economical.

4. Complex shape processing: precision grating sheet etching processing can easily deal with the complex shape of the grating sheet, such as with a subtle structure or a specific pattern of the sheet. And stamping processing for the processing of such complex shapes may have some difficulties.

5. Environmental protection: precision lenticular sheet etching process using chemical substances can be recycled, and the whole process can be carried out in a closed system, the impact on the environment is small. While stamping processing may produce waste and noise pollution.

6. High-precision surface treatment: Precision lenticular sheet etching processing can realize high-precision surface treatment, which is crucial to the performance of the lenticular sheet. Through the precision grating lenses etching processing, can get smoother, more accurate surface, thus improve the optical performance of the grating lenses.

7. Traceability: Each step in the precision lenticular sheet etching process can be accurately recorded and traced, which helps quality control and problem solving. And stamping processing, once the mold wear or failure, may affect the quality of a batch of products.

In summary, while stamping may be a reasonable option in some cases, precision lenticular sheet etching offers significant advantages in the manufacture of precision lenticular sheets. These advantages are mainly in terms of precision, material selection, production efficiency, complex shape processing, environmental protection, high-precision surface treatment and traceability. Considering these factors, as well as the key role of grating lenses in optical instruments, precision grating lenses etching processing should be the ideal choice for manufacturing precision grating lenses.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China