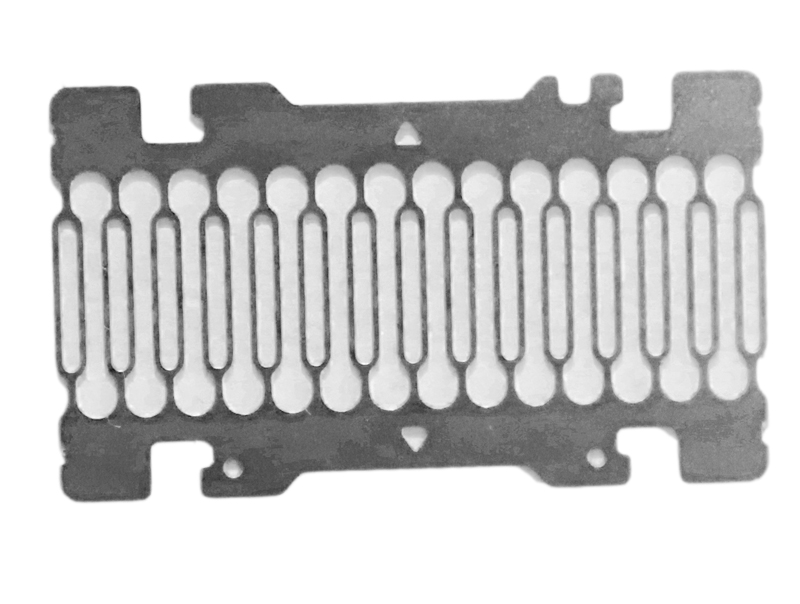

Stainless steel razor mesh cover etching processing is a common metalworking technique used to create mesh protective covers for personal care products such as razors. Below is a detailed explanation of stainless steel razor mesh cover etching processing:

Material Selection: Firstly, you need to select the stainless steel material suitable for making the mesh cover. Common stainless steel materials include 304 stainless steel and 316 stainless steel, which have good corrosion resistance and mechanical properties, and are suitable for razors and other products that require a high quality surface and durability.

Design and mold making: According to the design requirements of the razor, design the shape, size and pattern of the mesh cover. Then make the corresponding etching molds for etching the designed pattern and structure onto the stainless steel plate.

Etching process: The designed stainless steel plate is placed in the etching processing equipment to form the required patterns and structures on the stainless steel surface by chemical or electrochemical methods. Etching process can realize high precision, complex patterns and details, suitable for making mesh razor protective cover.

Cleaning and treatment: After completing the etching process, the stainless steel plate needs to be cleaned and treated to remove surface residues and treatments to ensure a clean, flat surface for the mesh cover.

Subsequent processing and assembly: After completing the etching process, the stainless steel mesh cover can be subjected to subsequent polishing, painting and other surface treatments to enhance its appearance and corrosion resistance. The mesh cover is then assembled with other parts of the razor to make the final razor product.

Stainless steel razor mesh cover etching processing technology has the characteristics of high precision, complex structure, good corrosion resistance, etc. It can meet the requirements of razor products on the quality and appearance of the mesh cover, and is a commonly used manufacturing process.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China