The precision microvia etching process is a high-precision, high-technology processing method widely used in microelectronics, precision machinery, aerospace and other fields. Through a series of delicate steps, this process is able to create tiny and precise hole structures on the surface of materials to meet various complex processing needs. The steps of the precision microporous etching process are described in detail below in order to give readers a deeper understanding of this technology.

First of all, material selection is the first step of the precision microvia etching process. According to the processing requirements and application scenarios, it is crucial to select suitable metal materials. Commonly used metal materials include stainless steel, aluminum alloy, etc. These materials have good corrosion resistance and mechanical properties, which can meet the needs of microporous etching. In the process of material selection, it is also necessary to consider the surface quality and dimensional accuracy of the material to ensure the smoothness of subsequent processing.

Next, the selected material is subjected to fine processing. This includes cleaning and pre-treatment of the material surface to remove impurities such as oil, oxides, etc. to improve the etching effect. In addition, the material is cut and ground according to the design requirements to obtain the desired shape and size. This step is of great significance to ensure the etching precision and quality.

After completing the fine processing, enter the mask production stage. The mask is the key part of the etching process, which determines the shape and size of the etching pattern. According to the design requirements, use high-precision drawing software to draw the required pattern and transfer it to the mask material. The selection of the mask material needs to consider its corrosion resistance, light transmission and other factors to ensure the clarity and accuracy of the pattern during the etching process.

After the completion of the mask, it will be closely affixed to the surface of the material to ensure that the pattern corresponds exactly to the material. At this point, the material needs to be exposed. Using a specific light source and exposure equipment, the pattern on the mask is projected onto the surface of the material to form a light-sensitive layer. This step requires precise control of the exposure time and intensity of the light source to ensure the uniformity and clarity of the light-sensitive layer.

After the exposure is complete, the chemical etching stage is entered. The use of a specific etching solution for the corrosion of the material, the chemical composition of the etching solution will have a chemical reaction with the surface of the material, thereby dissolving the part not covered by the mask. During the etching process, the concentration, temperature and etching time of the etching solution need to be strictly controlled to ensure that the etching depth and precision are controlled.

After the end of chemical etching, the material needs to be cleaned and dried. The use of deionized water and other cleaning agents to remove the material surface of the etching solution residues and impurities, while using drying equipment to thoroughly dry the material. This step helps to ensure the cleanliness and stability of the material after etching.

Finally, quality inspection and evaluation is performed. Use microscopes, measuring instruments and other equipment to test the size, shape, precision and other aspects of the etched microvia to ensure that the design requirements are met. At the same time, it is also necessary to assess the performance of the material, such as corrosion resistance, mechanical properties, etc., to ensure its reliability in practical applications.

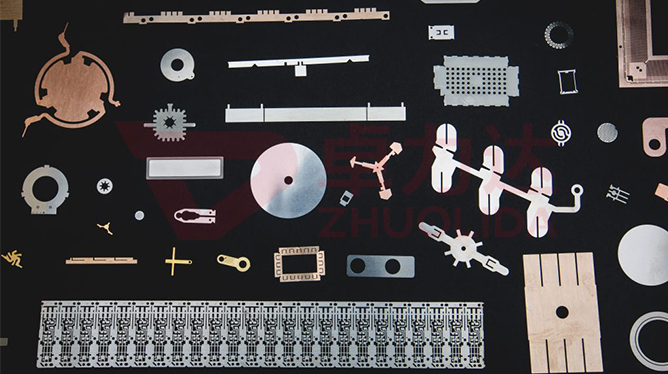

To summarize, the precision microvia etching process is a complex and delicate process that involves multiple steps such as material selection, fine processing, mask making, exposure, chemical etching, cleaning and drying, and quality inspection. Each step requires strict control of process parameters and operating techniques to ensure the quality and accuracy of the final product. With the continuous progress of science and technology and the continuous expansion of application areas, the precision microvia etching process will show its unique advantages and value in more fields.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China