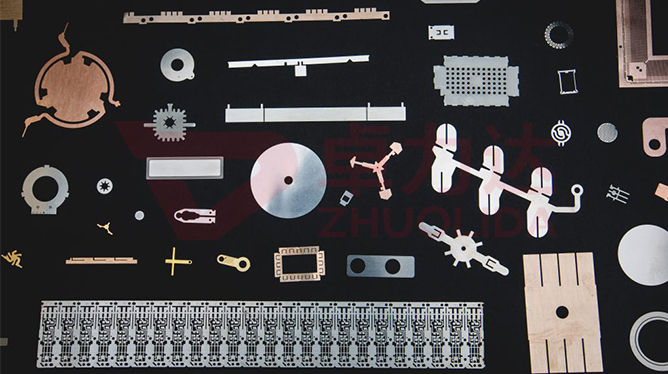

The common materials in metal etching are mainly stainless steel, copper and aluminum alloy, so what are the differences between these three metal elements?

Compared with copper and aluminum alloy, stainless steel is not easy to oxidize in the air, and the pretreatment process before etching is relatively simple. The etching solution uses ferric trichloride with strong oxidation to corrode the surface of stainless steel. The specific operation flow is to form an anti-corrosion layer on the part of stainless steel that needs to be protected by photosensitive ink, and put it on the assembly line of ferric trichloride. After completion, the protective film is removed by cleaning agent. Stainless steel can be etched by immersion etching and spray etching.

The difficulty coefficient of copper etching is relatively higher than that of Stainless steel etching. The main reason is that copper material is easy to oxidize after etching, but the etching solution can be made of stainless steel. The advantage of copper etching is that it does not consume chemicals and has greater freedom in etching solution.

The reaction between aluminum and chemicals will generate a lot of heat, and the reaction is very active. The waste chemicals can only be scrapped and cause serious pollution. The aluminum fading ink needs nitric acid, hydrofluoric acid, etc. Nitric acid has a strong smell, and hydrofluoric acid has a very high toxicity, so the etching risk of aluminum is also high.

Zhuolida etching does not etch aluminum, so stainless steel, copper, titanium, molybdenum and other materials can be etched.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China