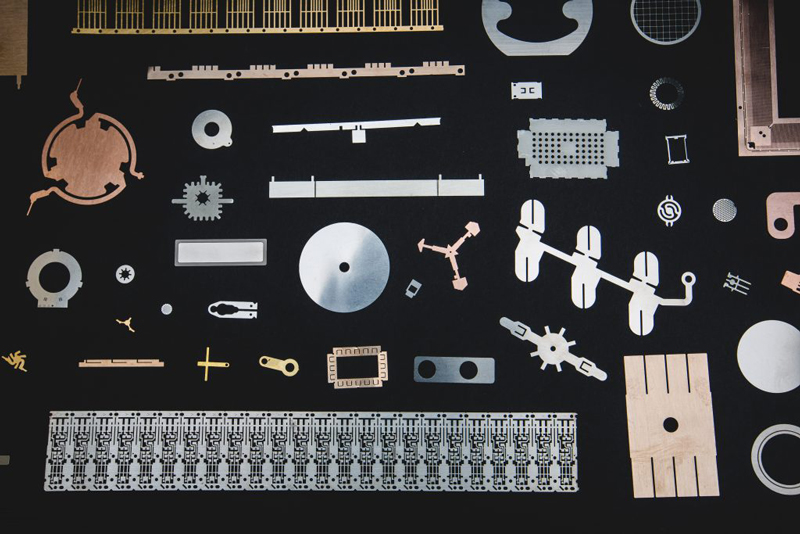

Metal filters are widely used, mainly for wind protection, filtering, dust prevention, ventilation, protection, etc. Their application fields involve electronics, medical care, electrical appliances, hardware, etc. Automotive precision products include vapor-liquid filtration, intelligent automotive oil cores and automotive horn nets. The processed materials are mainly 304 stainless steel, 316 stainless steel, copper, titanium alloy, etc. The filter screen is mainly processed by punching and etching, and the processed thickness is 0.03mm, 0.05mm, 0.08mm, 0.1mm, 0.15mm, 0.18mm, 0.2mm, 0.25mm, 0.3mm, 0.4mm and 0.5mm.. 0.65 mm, 0.63 mm, 0.75 mm, 0.8 mm, 0.9 mm, 1 mm, stamping can not meet the processing technology of 0.03MM thickness limit, but it can be done by etching. The advantages of etching metal filter screen are introduced below:

1. The etched filter screen has high flatness, no burr, smooth and delicate surface, and is easy to clean and maintain without changing the material characteristics. The surface treatment of nickel plating and oxidation treatment can improve the service life of the filter screen.

2. Etching the metal filter can change the design at will, reducing the design and development cost.

3. Etched filter screen can ensure extremely high precision, and the highest precision can reach+/-0.01 mm..

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China