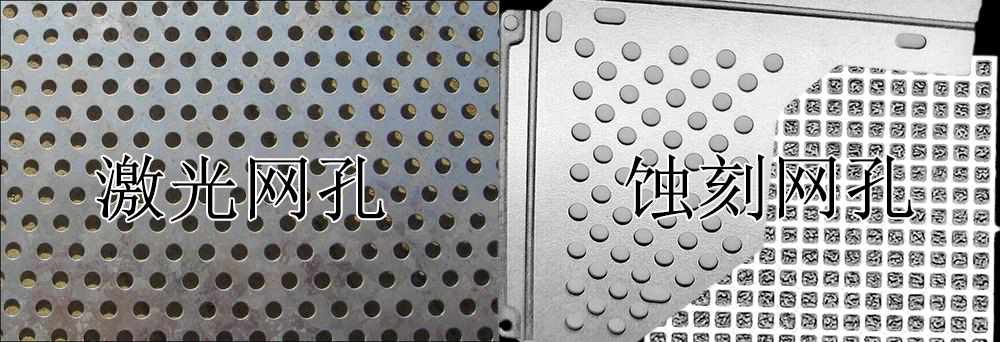

Laser mesh vs. etched mesh, which is better? This is a topic that has been debated by many technology enthusiasts and industry experts. Today, we will find out!

Laser mesh processing speed, high precision, able to process a smaller aperture, but for a large area of smaller hole processing effect is not as good as etching processing. Etching mesh processing speed is slow, but due to the use of metal film and chemical corrosion for large areas of the hole processing effect is better, and cheaper.

Laser mesh that laser perforation, it uses high energy laser beam to irradiate the surface of the material, so that it produces high temperature region, and then through the high temperature region of the gasification effect to achieve perforation. The advantages of laser perforation are: high precision of hole diameter, good quality of holes, fast speed, can handle a variety of materials, suitable for thin plate materials, and can also be processed on complex curved surfaces. However, there are some disadvantages, such as high cost, some damage to the material, not suitable for processing ultra-thin or thick plate materials. In addition, laser processing requires expensive equipment and energy costs, while etching processing requires a large number of chemicals, causing pollution to the environment, as a certain strength manufacturers are established sewage treatment cycle system, able to reduce pollution to the national standard value. Etching mesh also has some disadvantages, such as slow speed, processing depth is limited, the requirements of the material is relatively high, but can realize the material thickness between 0.01mm-2mm, processing out of the mesh will not be laser perforation produced by the deformation or burning sensation, as well as the side of the mesh processing burrs. Therefore, enterprises in the choice of processing methods need to consider the cost and environmental factors. Laser mesh and etched mesh are not completely opposite, they have different applications in different fields.

In addition to cost and effect, another important factor is the difficulty of processing. Laser processing requires specialized technicians and high-end equipment, while etching is relatively simple and requires only a certain knowledge of chemistry. Therefore, for companies that mass produce functional products, etched mesh may be more suitable.

When choosing laser mesh and etched mesh, you need to choose according to the actual situation. If high precision and small hole diameter are required, then laser mesh is a better choice; if low cost and large processing area are required, then etched mesh is more suitable. No matter which way to choose, we need to focus on environmental protection and cost control, so that technological progress and sustainable development complement each other.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China