Have you ever wondered how reciprocating razor blades are made?Today, let's unravel this mystery and see how this tiny razor blade accomplishes its great mission!

Reciprocating razor blades are made up of hundreds of tiny gears, each with a different shape and size. During the manufacturing process, these gears are ground, polished and inspected many times before they are assembled into complete razor blades.

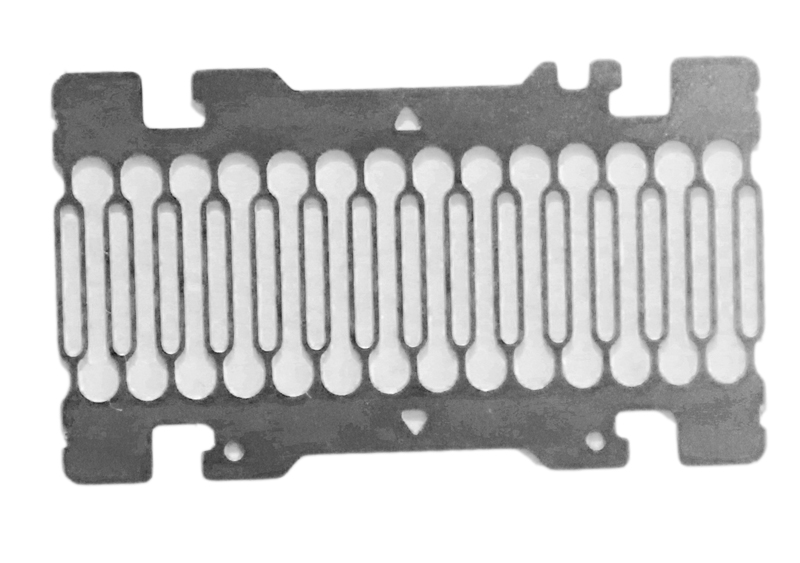

The difficulty in making reciprocating razor blades lies in the control of precision. The size, shape and position of each gear must be accurate to the millimeter level or the quality of the entire razor blade will be compromised. To ensure that each gear meets the requirements, manufacturers use high-precision processing equipment and strict quality control processes. Which etching reciprocating razor blade was born, through the etching process can effectively guarantee the etching out of the product surface smooth burr-free, the product is not deformed, the use of metal film production cost is low, precision control to achieve micron-level tolerances, etching reciprocating razor blade gradually replace the traditional processing methods, etching reciprocating razor blade effect and then through the subsequent grinding, nickel-plated treatment, skin The effect is better.

In addition to the difficulties of production and processing, the design of the reciprocating razor blade is also very delicate. It swings back and forth quickly during shaving, making it easier for the blade to fit the skin and reducing discomfort during shaving. It also automatically adapts to different shaving angles, making your shaving easier and faster.

Reciprocating razor blades are a very precise processing technology, and their production requires high-precision processing equipment and strict quality control processes. Only in this way can we ensure that the quality and performance of each shaving blade can be guaranteed. Have you ever used reciprocating razor blades? Feel free to share your experience of using them in the comment section!

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China