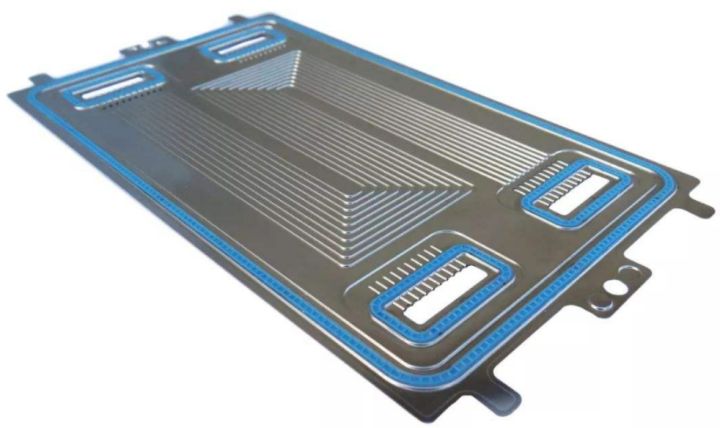

The development of new energy fuel cells shows its potential of clean, funny and reliable power supply. Bipolar plate is a key component of fuel cell, which has the functions of providing electrical connection, transporting reaction gas, dissipating reaction heat and removing by-products. At present, bipolar plates are divided into metal bipolar plates, graphite bipolar plates and composite bipolar plates. Here is a brief introduction to the metal bipolar plate.

Metal bipolar plate has good electrical conductivity, thermal conductivity, machinability, fewer manufacturing processes compared with graphite bipolar plate, and the mass production process of ultra-thin metal bipolar plate is relatively mature, which can greatly reduce the cost. Etching is used in the manufacturing process of metal bipolar plate, which has been widely used in stainless steel, aluminum alloy, titanium alloy, nickel alloy, copper alloy and metal matrix composites. Because of its low corrosiveness, coating protection is used in the subsequent processes. The corrosion of metal bipolar plate is mainly caused by the reduction of the protective metal oxide layer at the anode due to the existence of reducing environment, which forms hydride and dissolves the metal in water, and the metal is mixed into the fuel flow through water vapor, which increases the risk of proton exchange membrane pollution and adversely affects the activity of catalyst layer. At the cathode, the existence of oxidation environment will greatly increase the corrosion rate of metal bipolar plate, which will lead to performance degradation and even premature failure of the whole battery stack.

Etching of metal bipolar plates has the following characteristics:

1. Adopting etching process, the precision is high, which can reach ±0.01mm (different materials have different thicknesses).

2. The surface of the product is smooth, without bumps, pits, burrs and warpage, and the mesh is flat and without deformation. It does not need grinding and polishing, and it is self-care after flattening.

3. Fine etching processing size (aperture 0.1mm, line width 0.1mm), accurate positioning (±0.03mm) and uniformity.

4. Short production cycle, quick response and convenient design modification.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China