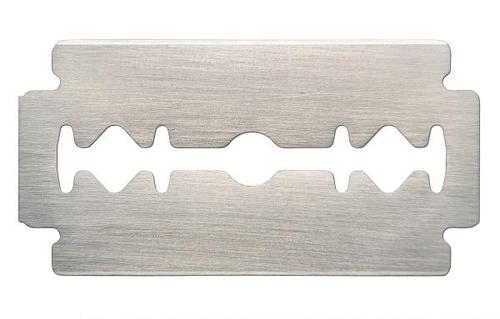

The factory of shaving blades in Eisfield, Germany can produce 1.3 billion blades every year. Shaving blades are exposed to high humidity environment regularly. The preferred steel is hard alloy steel, which can ensure the hardness to keep its shape, has enough ductility and is made of non-corrosive steel alloy. The shaving blade contains 12% to 14.5% chromium, about 0.6% carbon, and the rest is iron and trace elements.

The stainless steel shave blade can adopt a process which can ensure that that product line are uniform, free from burrs and notches, namely etching proces, and the thickness of the material is 0.08 mm, 0.1 mm, 0.12 mm, 0.15 mm, 0.18 mm and 0.2 mm. The etched shaving blade can be produced in large quantities with high precision and can also meet the assembly requirements of different products; Low mold opening cost, which can be changed at will according to the requirements of the personnel involved, and the cost is low. Stainless steel shaving blades with complex shapes can also be etched without additional cost.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China