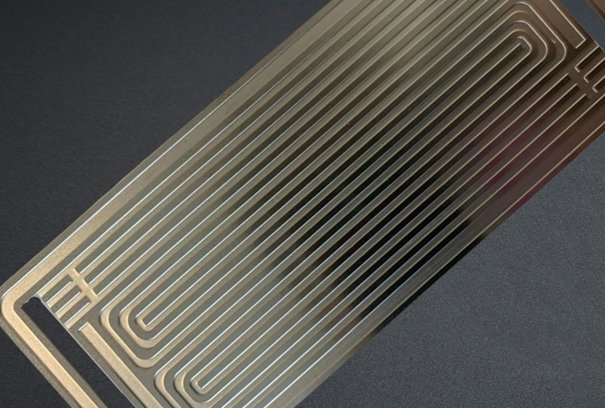

The field of new energy vehicles is composed of fuel cell stacks, which are the core parts of fuel cells, including membrane electrodes, gas diffusion layers, bipolar plates, etc. Metal bipolar plates are important components of fuel cells, also known as collector plates, which can provide gas flow channels to prevent hydrogen and oxygen from channeling in the gas chamber of the battery, and establish current channels between the anode and cathode in series to collect conductive current and separate reaction gases on the premise of maintaining a certain mechanical strength and a good lease term. Its existence directly affects the weight and volume of the stack, and also determines that the stack plays an important role in power output and service life. At present, bipolar plates are mainly divided into graphite bipolar plates, compliant bipolar plates and metal bipolar plates.

The machining of bipolar plate is mainly based on etching, among which CNC, laser machining and stamping are all unsuitable to varying degrees. The stamping function of bipolar plate can seriously damage the material characteristics and lead to deformation. It is expensive to re-open the mold after changing the design drawings, and the cost of CNC machining is high. The accuracy of some wire slots can not meet the requirements, and laser machining can not meet the needs of half-engraving. Etching metal bipolar plate has the following advantages:

1. Low mold opening cost, which can be arbitrarily changed according to the designer's design, and the cost is low.

2. Semi-etching can be realized with high precision, and the highest precision can reach+/-0.0075 mm..

3. For products with complex shapes, the arrangement can also be etched without additional cost.

4. There are no burrs and pressure points, the product is not deformed, the material properties are not changed, and the function of the product is not affected.

5. Thick and thin materials can be processed in the same way to meet the requirements of different assembly components.

6. Almost all metals can be etched, and there is no restriction on various pattern designs.

7. Manufacturing all kinds of metal parts that cannot be finished by mechanical processing.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China