Metal mask plate processing is a widely used process in microelectronics manufacturing that chemically or physically transfers metallic materials from a mask plate to a semiconductor substrate. This processing method offers many advantages, which are described in detail below.

1. High precision and resolution

Metal mask plate etching process can realize high precision and high resolution manufacturing. By selecting the appropriate etching solution and process conditions, the etching rate and anisotropy of the metal material can be precisely controlled. This precise etching process can obtain metal mask plates with fine features and complex structures, thus greatly improving the performance and integration of semiconductor devices.

2. Applicable to a variety of metal materials

Metal mask plate etching process can be applied to a variety of metal materials processing. Different metal materials have different characteristics and application areas, so you can choose the appropriate metal material for etching processing according to the need. For example, copper and aluminum are widely used in the manufacture of conductive and connecting layers, while nickel and chromium are used to manufacture contacts and leads.

3. Realization of complex structure processing

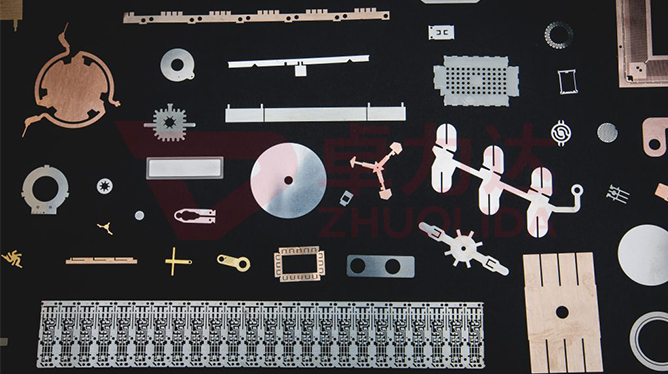

Metal mask plate etching processing can deal with a variety of geometric shapes and structures on the mask plate, such as slots, holes, columns, etc., thus enabling the processing of complex structures. Through the use of different etching solutions and process conditions, a variety of different structures can be created on the metal mask plate to meet the manufacturing needs of various semiconductor devices and integrated circuits.

4. High yield and low cost

Metal mask plate etching process has the advantages of high yield and low cost. In mass production, etching processing usually adopts automated production lines, which can realize rapid and continuous production. In addition, by selecting the appropriate etching solution and process conditions, low-cost and high-efficiency processing of metal materials can be realized, thus reducing production costs.

5. Good compatibility

Metal mask plate etching processing has good compatibility with other manufacturing processes. For example, it can be combined with photolithography process to realize high precision and high resolution manufacturing. In addition, etching processing can also be compatible with evaporation, sputtering and other processes to realize the multilayer structure and versatility of the metal mask plate. This good compatibility makes the metal mask plate etching processing in microelectronics manufacturing is widely used.

In conclusion, metal mask plate processing has the advantages of high precision, high resolution, applicable to a variety of metal materials, realizing complex structure processing, high yield and low cost, and good compatibility. These advantages make etching processing one of the key indispensable technologies in microelectronic manufacturing, providing important support for the manufacture of semiconductor devices, optoelectronic devices and integrated circuits.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China