Develoable alloy etching provides precise dimensional control and fine detailing. This is important for components such as deleterious alloy encapsulated covers that require high precision manufacturing. Etching allows for precise patterning and contouring by means of precisely controlled chemical reactions, ensuring that the size and shape of the cover plate meets the design requirements.

1.The etching process of develoable alloy encapsulated cover plate can improve the production efficiency. Compared with traditional machining methods, such as milling, turning or drilling, etching processing can handle multiple material surfaces at the same time and realize mass production. This greatly reduces production time, improves productivity, and thus reduces production costs.

2. The etching process of develoable alloy encapsulated cover can reduce scrap and minimize tool wear. Since etching processing is a chemical reaction, it does not produce chips like machining, thus reducing the generation of scrap. At the same time, because there is no physical contact, etching process will not wear the tool, which greatly extends the service life of the tool.

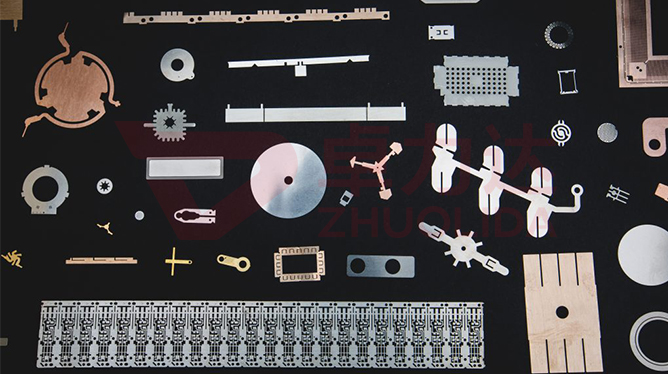

3. The etching process of deformable alloy package cover can provide more design flexibility. Through different etching techniques, a variety of complex patterns and designs can be realized on the deleterious alloy package cover to meet different application requirements.

4. Develoable alloy package cover etching process has high precision and high repeatability. This enables the production of highly consistent and reliable covers, thus improving product quality.

5. Develoable alloy package cover etching process usually uses environmentally friendly chemicals, such as alkaline solution or acidic solution. During the etching process, these chemical reagents will decompose the unwanted metal parts without generating toxic and hazardous waste gas or waste liquid, thus ensuring the environmental friendliness of the production process.

To summarize, the etching process is chosen for develoable alloy encapsulated covers because it provides precise dimensional control, improves productivity, reduces scrap and tool wear, offers more design flexibility, is highly accurate and repeatable, and is an environmentally friendly production process.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China