Metal code disk etching processing is a high-precision manufacturing process that is widely used in a variety of fields, such as instrumentation, optical components, microelectronics industry and so on. This processing method has many advantages, the following are some of the main features:

1. High precision: metal codeplate etching processing can provide high-precision codeplates with very high resolution and repeatability. Through this process, code disks with smooth surfaces and fine scales can be manufactured to meet the needs of high-precision measurement and positioning.

2. Wide applicability: metal code disk etching processing is applicable to a variety of materials, including stainless steel, nickel-iron alloy, copper alloy, tungsten alloy and so on. This enables the process to cope with a variety of complex environments and special requirements, such as high temperature, low temperature, strong magnetic field, etc..

3. High flexibility: metal code disk etching processing can use different etchant and process parameters to obtain different surface roughness and scale depth. This makes the process highly flexible and can be customized according to different needs.

4. Cost-effectiveness: Compared with other processing methods, the cost of metal code disk etching process is relatively low. The process can be used in mass production to improve productivity and reduce unit costs.

5. Environmentally friendly: metal code disk etching processing does not produce waste and harmful substances, it is an environmentally friendly manufacturing process. In the production process, the etching solution can be recycled, reducing the pollution of the environment.

6. Good Repeatability: Because the metal code plate etching process uses a standardized process, its products have good repeatability. This enables the process to provide products of consistent quality and reduces quality risks.

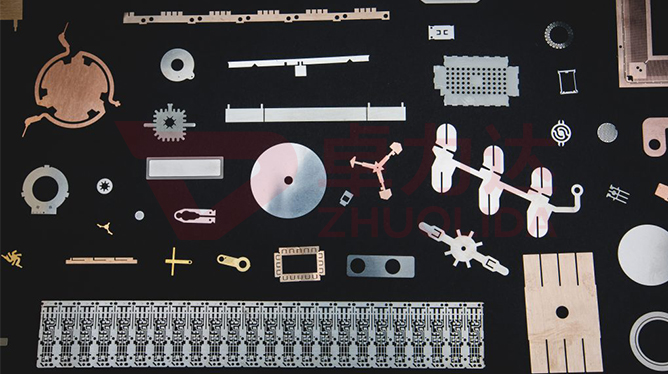

7. Wide range of application: metal pallet etching processing can not only be used for the manufacture of flat pallets, but also to create a variety of shapes and structures of parts. This makes the process in a variety of fields have a wide range of application prospects.

In short, metal yard plate etching processing is widely used in many fields with its high precision, wide applicability, flexibility, cost-effectiveness, environmental protection, good repeatability and wide range of application.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China