With the vigorous development of consumer electronic products, the technology has changed from high, precise and sophisticated, the product life cycle has been iteratively updated, and the products are multi-model and small-batch. At the same time, the tolerance of product accuracy is required to be within microns, so the traditional technology can no longer meet its requirements, which also drives the speaker sound network to pursue the ultimate in technology.

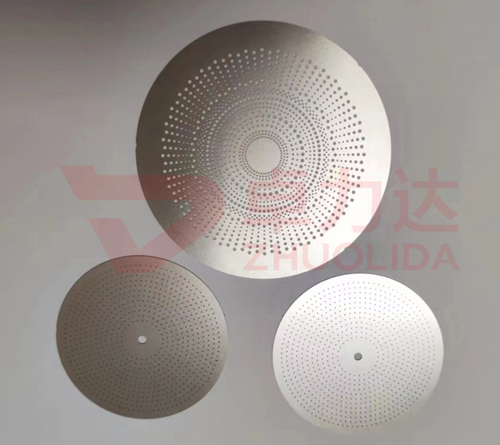

The technology of speaker sound network is mainly stamping, laser, etching and electroforming. The traditional speaker sound network adopts stamping technology, which has no strict requirements on appearance. The spacing between meshes is relatively large, so stamping needs to make molds, and the cost is relatively high, which cannot change the design style. Although the processing cost is relatively high and the speed is high, the cost of molds is not low. It is slow to process the holes with laser in the speaker sound network, and it is only suitable for the speaker sound network with a relatively small number of holes, and the edge of the network will be blackened due to laser. In terms of high precision, the speaker sound network can be etched, the minimum precision can reach 0.01MM, the standard thickness is 0.03, 0.05, 0.08, 0.1, 0.2, 0.25, 0.3mm, and the selected material standard is stainless steel SUS304, 403, 304H, with uniform lines, no burrs and no gaps.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China