After the "Government Work Report" of the NPC and CPPCC in 2021, China promised to achieve peak carbon dioxide emissions by 2030 and carbon neutrality by 2060. Under the guidance of the trend, the prospect of new energy development is very impressive. With the development of new energy vehicles, a mature and complete industrial chain has been gradually formed. Power battery is an important part of new energy vehicles and plays a decisive role in key indicators such as cruising range, vehicle life and safety.

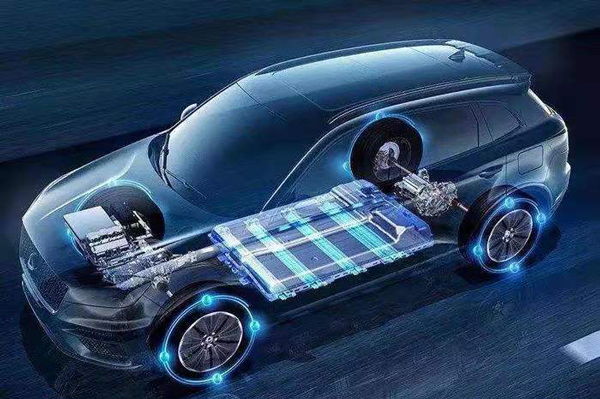

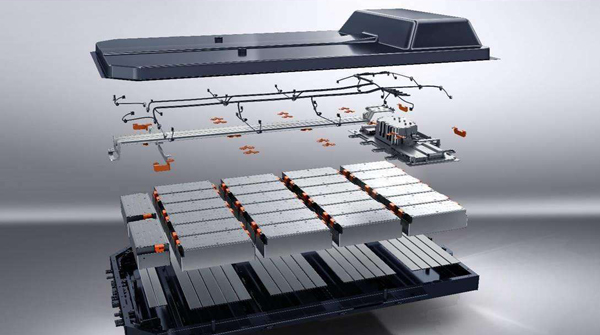

The new energy vehicle is a battery pack with a length of 2 meters, a width of 1.4 meters and a height of 25 centimeters, which is assembled by hundreds to thousands of small batteries. The mileage of new energy electric vehicles depends on the number of battery packs, which is known as blade batteries. Tesla models basically use Panasonic's ternary lithium battery, and BYD uses self-developed blade battery, whose predecessor is lithium iron phosphate battery.

In the field of new energy vehicles, the battery can be processed by etching. The main reason is that etching can guarantee the product characteristics well under high precision and strict tolerance, which is helpful to better play the stability of new energy vehicles. The heating film of automobile lithium battery is also finished by etching, and the difficulty coefficient of mechanical processing is large. The metal foil and metal wire in the heating film of automobile ensure the material characteristics, stress and hardness. Compared with other processes, the cost of research and development and batch revision by etching has higher convenience and lower cost advantage.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China