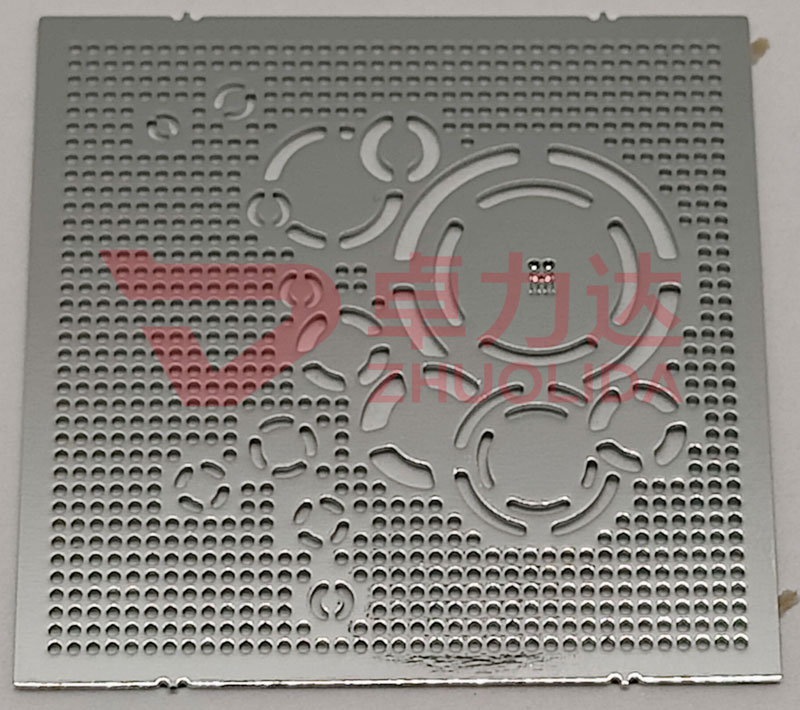

In the process of metal etching, customers often design the aperture to be smaller than the thickness, or even beyond the limit tolerance range. For example, in the process of metal filter disc, the thickness is 1.5MM, and the aperture design tolerance is 0.02 mm. If it is still conventional, this etched filter screen cannot meet its design requirements, because the chemical etching process is to dissolve the metal by spraying chemicals. In the early stage of metal processing, raw materials are treated with a wet film by a roller, and the pattern made of metal film is exposed and developed after the wet film is dried. After entering the etching, various problems will occur when the pattern is formed by chemical spraying due to the design tolerance limit, such as the gap between holes is too narrow, which leads to corrosion break, the tolerance limit cannot be engraved or the scale is uneven, thus forming scrapped products.

So how can metal etching solve this problem? It is necessary to consider that the size of the aperture is determined by the thickness in the drawing process, and the reasonable interval between the thickness and the aperture is 1.5 times. If the aperture is smaller than the thickness, it cannot exceed this reasonable interval value, but it must be designed as a double-sided etching method. For example, in the etching process of coffee filters, one side is often designed to be etched into a large aperture and the other side is etched into a small aperture, which is collectively called horn mesh, but the gap cannot be too narrow. Otherwise, it is impossible to meet the requirements by etching. On some large screen plates, the thickness is 2.0MM, and the etching aperture is also 2.0 mm. Strictly speaking, etching cannot meet this requirement, but it is also necessary to make horn meshes in the process of metal etching and manufacturing.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China