The International Rubber & Plastic Exhibition officially kicked off in the new Shenzhen Pavilion in full swing. The awe-inspiring high-precision equipment made people marvel, and they constantly lamented the development mileage of China from low-end products to high-end precision equipment.

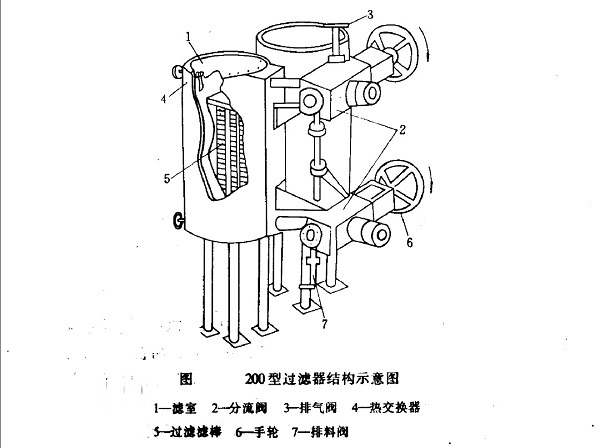

Melt filter is an important equipment for high-speed spinning and fine denier spinning. By continuously filtering polymer melt, impurities and unmelted particles in the melt are removed, so as to improve the spinning performance of the melt and ensure the spinning quality. There are many types of melt filters, such as portable melt filters. The inlet and outlet are designed as C-type and Z-type, and the filtering area can reach 0.2-40m2. The filtering methods include butterfly sintered felt, candle folded sintered felt, butterfly flat screen, candle flat screen, etc. The filtering area of continuous switching filter is 1-80m2, and the operation is flexible. The water pressure is 24mpa, and there is no leakage. The shapes of melt pipes are straight pipes, L-shaped bends, Z-shaped bends, etc.

Melt filter involves porous filter screen, which can be completed by etching. The surface of the etched filter screen is flat and smooth, and it can be well fused with the container without burr. The etching thickness of the filter screen can reach 2.0mm, and the laser processing does not affect the processing process, but the surface has a certain roughness, which is completely absent from the etching processing.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China