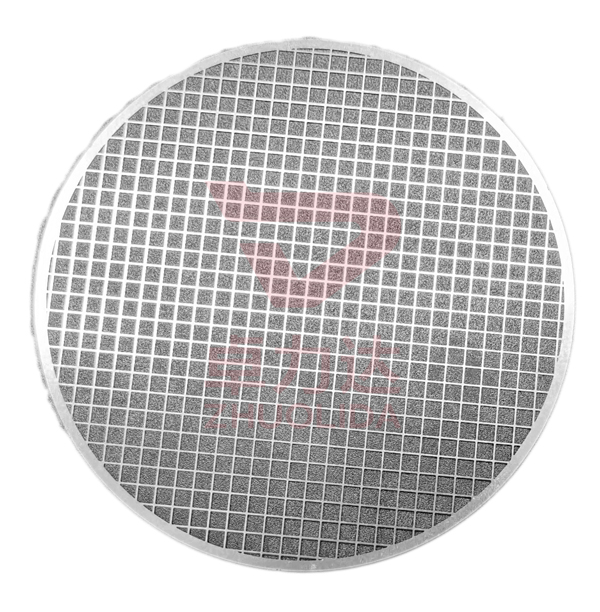

There are two kinds of metal mesh produced by different processes: stainless steel punched mesh and stainless steel etched mesh.

Stainless steel punching screen is a filter screen material produced by stamping process. By punching different holes in the material to meet different product requirements, the materials used for punching screen are: stainless steel plate, low-carbon steel plate, galvanized PVC cold-rolled coil plate, etc. Its basic specifications and methods are mainly as follows:

1. The thickness of rolled plate is 0.2MM-1MM, and the length is 20M.

2. The aperture is 1.5MM-10MM.

3. The sheet thickness is 0.2MM-20MM, and the width * length < =1.5M*5M.

4. The aperture is 0.5MM-200MM.

Stainless steel etching screen is exposed by plate making, developed, covered with photosensitive ink, and removed by etching, so that the metal contacts with high-concentration mixed chemical solution, and two positive patterns are used to achieve the effect of dissolution and corrosion by chemical immersion grinding from both sides, forming concave-convex or hollow molding effects. What are the advantages of stainless steel etching net?

1. Low mold opening cost, free change of metal film design style and low cost.

2. The half-engraving depth etching of the metal surface can be realized.

3. Extremely high precision, up to 0.0075 mm.

4. Complex shapes can also be etched without adding new cost.

5. No burr, no pressure point, no product deformation and no change in material properties.

6. Almost all metals can be etched, and there is no restriction on various pattern designs.

The thickness of stainless steel etching screen can be etched between 0.01MM-2MM and 2 mm, which is especially suitable for high-precision instruments and equipment. Chemical etching can meet the production requirements in batch production.

Whether stainless steel punching screen or stainless steel etching screen are carried out by two processes, we can consider which method is suitable in the process of selecting processing methods from the thickness accuracy.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China