With more than 20 years of roots in the automotive field, Toyota Motor Group has created the world's largest fuel cell patent portfolio. From the installation of hydrogen manufacturing knife infrastructure and its application in Toyota FCEV, Toyota Group has implemented a vertical innovation and integration process. In the manufacturing process of hydrogen fuel, Toyota Motor Group includes solid oxide electrolyzer, high performance proton exchange membrane electrolyzer and photocatalytic water. Toyota Group is also engaged in the patent of hydrogen carrier for storage and transportation.

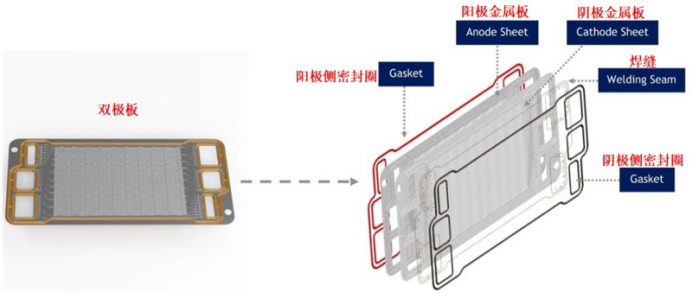

A metal bipolar plate is mainly composed of five parts: anode side sealing ring, anode metal plate, cathode metal plate, weld and cathode side sealing ring. The anode metal plate and the cathode metal plate are combined and welded, and the reaction gas and cooling liquid can be prevented from channeling each other as much as possible by using the male and female sealing rings, and the reaction gas and cooling liquid can also be prevented from leaking out.

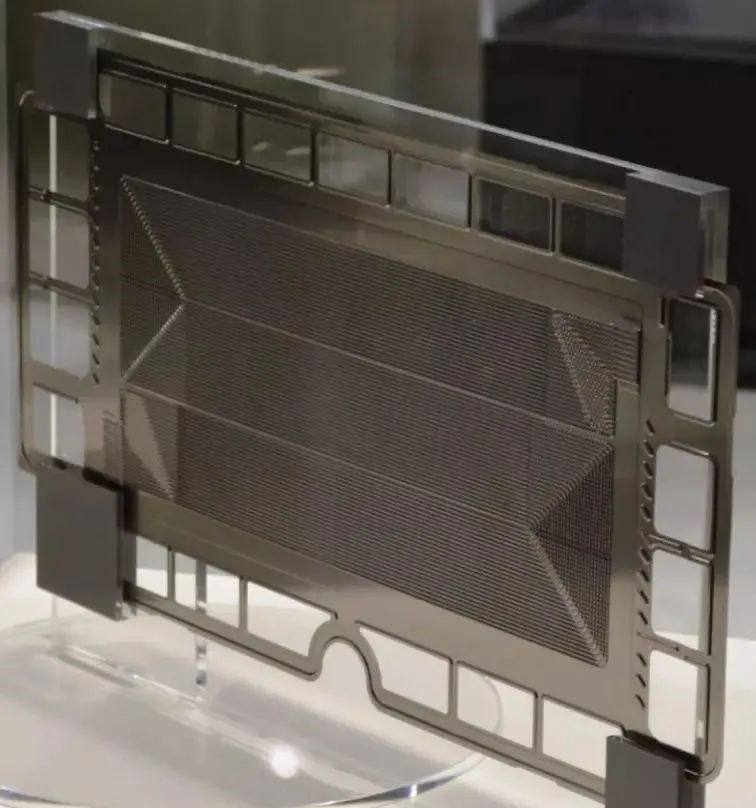

The design of metal bipolar plate mainly consists of three parts: import and export area, reactant transition area (reactant gas distribution area) and effective reaction area. In engineering, the flow channels of reactant transition zone and reaction zone are optimized by computational fluid dynamics CFD, and the inlet and outlet areas include hydrogen channel, air channel and cooling channel. The reactant transition zone aims to ensure that the reactants can be more evenly distributed in the reaction zone and the electrochemical hardening can react evenly and fully.

The metal bipolar plate is etched, mainly because the surface of the bipolar plate can be smooth and burr-free, and the etching can meet the thickness of 0.01-2MM. The design of the metal film is changed without increasing the cost, and the batch production can meet the requirements.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China