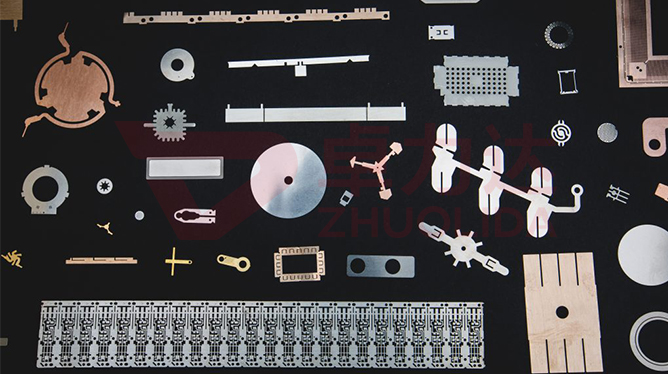

Stainless steel etching is a finely crafted and complex process that involves a wide range of knowledge in chemistry, physics and mechanical engineering. The following is its detailed process flow:

1.Material preparation:

Select the appropriate stainless steel material, such as 304 stainless steel, 316 stainless steel, etc., depending on the use of the desired product and the environment. Compared with other metals, stainless steel has excellent corrosion resistance and beautiful surface, which is very suitable for etching processing.

2. Sheet processing:

Processing stainless steel materials into desired shapes and sizes. This usually involves mechanical processing steps such as shearing, cutting and stamping.

3.Surface treatment:

Stainless steel etching requires surface treatment of the stainless steel plate to remove surface impurities such as oxidized layer, grease and dust. This usually includes grinding, sandblasting, cleaning and other steps. Surface treatment is a key step to ensure the etching effect, must ensure that the surface is free of impurities and smooth.

4. Coating:

Coat the surface of the stainless steel plate with a layer of corrosion-resistant protective adhesive. This layer of glue can resist the erosion of acid in the etching process, to protect the plate from damage. At the same time, the thickness and uniformity of the glue will also affect the precision of etching.

5. Exposure:

Use ultraviolet light or electron beam to transfer patterns or text, etc. to the adhesive layer. This is achieved by transferring the pattern or text, etc. to the photosensitive adhesive layer. After exposure, the adhesive layer that has not been exposed to ultraviolet light will remain resistant to corrosion.

6. Developing:

The unexposed photosensitive adhesive layer is dissolved and rinsed off with a solvent to make the pattern or text, etc., appear. This step needs to control the concentration and temperature of the solvent to ensure the integrity and precision of the adhesive layer.

7. Etching:

Will be coated and exposed stainless steel plate into the acidic solution, the acidic solution will erode the stainless steel surface is not protected by the adhesive layer, so as to form the desired pattern or text, etc.. Etching time, temperature and type of acid will affect the effect of etching.

8. Degumming:

After the stainless steel etching is completed, the adhesive layer needs to be removed to obtain the final product. This is usually achieved by heating, mechanical scraping or chemical dissolution. Degumming process needs to protect the stainless steel surface from damage, but also to ensure the accuracy and quality of the product.

9. Cleaning and antirust treatment:

After removing the glue layer, the stainless steel surface needs to be cleaned to remove the residual glue residue, acid and other impurities. After cleaning, rust prevention treatment is needed to protect the stainless steel surface from oxidation and corrosion. Commonly used antirust treatment includes applying antirust oil, passivation treatment and so on.

10. Quality inspection and packaging:

Quality inspection of the completed stainless steel etching products, including size inspection, surface quality inspection, precision inspection, etc.. Qualified products need to be packaged to protect the product from damage during transportation and storage.

In short, the stainless steel etching process is a delicate and complex process that requires knowledge and skills in many areas. From material selection to final packaging, each step requires careful operation and strict control to ensure the quality and precision of the final product.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China