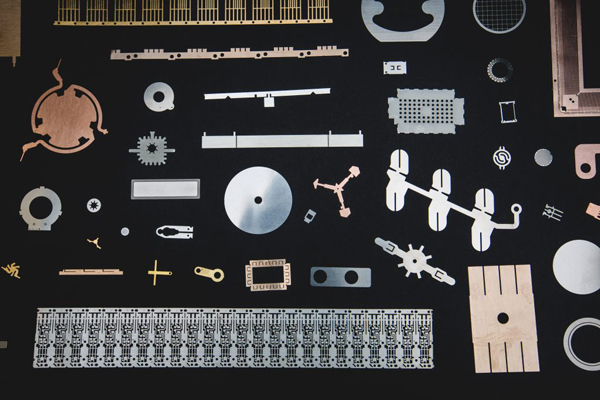

Mesh processing process often encounter customers on the laser processing and etching process between the existence of different views, in the end, whether to choose the laser processing or choose the etching process way. Here we will introduce the two processes are different.

From the effectiveness of the way the laser processing mesh faster than the etching of mesh, etching processing of the main component is ferric chloride and other chemical compounds need to be fused through the water to produce a strong acid, it takes time to precipitate, in the process of considering the need to establish the metal FILM and chemical corrosion of the configuration of the agent, while the laser processing using a high-energy laser beam to irradiate the surface of the material, so that it produces high temperature areas, and then through the high-temperature The gasification effect of the region to achieve perforation processing, eliminating many of the complexities of the process, but this processing method in the case of large areas of aperture, etching processing network is better than the effectiveness of laser processing and relatively inexpensive.

Laser processing network advantages of high precision aperture, hole quality, suitable for thin plate materials and complex surface processing, but due to the use of gasification perforation, the metal material has a certain degree of damage, the thinner the thickness of the material, the laser processing requires expensive equipment and energy costs, resulting in high processing costs, while the etching process due to the use of chemicals in the way, to a certain extent on the environment to produce a great deal of Pollution, so the strength of the factory using fully automated recycling system to reduce pollution below the national standard value, etching, although the speed is relatively slow, but can achieve between 0.01mm-2mm material thickness, etching out of the mesh so that the product is not deformed or burning sensation, and the surface does not produce burrs.

Whether to choose laser processing or etching processing needs to be based on their own processing needs to decide, the requirements of higher precision, less aperture can be used in the form of laser processing, aperture more, mass production costs are low, you can choose to etching processing to be carried out.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China