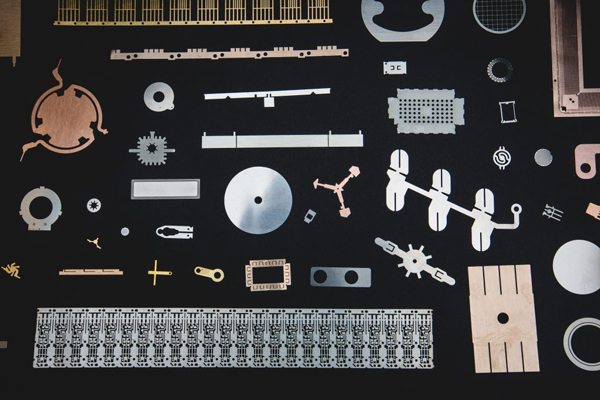

How much do you know about stainless steel plate processing? Is it through CNC processing, laser processing or stamping processing? Today we would like to introduce a different process, that is, etching processing, etching processing for stainless steel, etching thickness between 0.01MM-2MM, Stainless steel etching plate, its corrosion resistance, abrasion resistance, not easy to rust, safe and environmentally friendly, recyclable, stable, so that it has become the first choice of materials for all walks of life. Etching process is divided into shallow etching and deep etching in two ways, in which deep etching using chemicals using half-engraving, with a consistent concave-convex, fine pattern characteristics. Stainless steel etching plate has a wide range of applications, from hotel and KTV decoration, to chemical process, LED base lamps and lanterns, to food equipment, medical equipment, automobile component panels, everything!

The process and technology behind the stainless steel etching plate is very mysterious and makes people full of curiosity. Through the etching out of the stainless steel surface flat and delicate, no burrs will not produce burning sensation and burrs, which is not the same as other processes.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China