Imagine a silicon wafer that can be etched into a film up to 200 meters long. Isn't it amazing? Today, we would like to introduce you to this amazing technology!

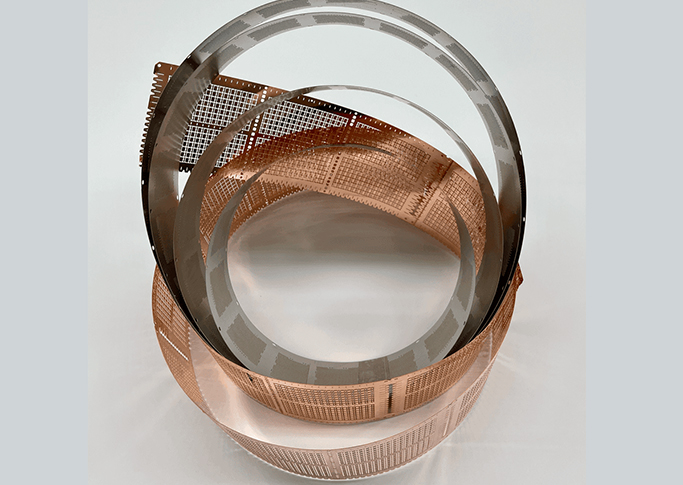

Reel-to-reel etching is a highly detailed, highly automated chemical etching method, for the volume of material to achieve fully automated continuous etching process, to facilitate the production of batch etching, what is the reel-to-reel continuous etching, that is, continuous seamless exposure to achieve the reel-to-reel impact of the process of transferring the two consecutive images will be aligned with the link together. Want to realize the volume to volume continuous etching must be completed volume to volume exposure, volume to volume exposure process: unwind - buffer - clean - film plate alignment - substrate alignment - gap alignment - exposure - transfer - buffer - winding. Seamless roll-to-roll continuous etching is suitable for stainless steel, copper, nickel sheet, iron and other thin and light metal materials, etc., the thickness of the etching between 0.01mm-2mm, other process processing methods will lead to deformation of the product, but also can not achieve seamless roll-to-roll continuous etching processing form, etching process can be very good protection of the hardness of the metal material, strength, formability and other physical properties, not easy to produce curled edges Burr, and etching can do products without burrs.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China