There are several factors involved in making etching stainless steel difficult. Stainless steel as a special metal material, its chemical properties and physical structure make the etching process complex and challenging. The following will be from the characteristics of stainless steel, etching principles, technical difficulties and practical challenges, etc., detailed description of why etching stainless steel is difficult.

First of all, the chemical composition and physical properties of stainless steel determine the difficulty of its etching. Stainless steel is mainly composed of iron, chromium, nickel and other elements, these elements give stainless steel excellent corrosion resistance and strength. The presence of chromium makes the surface of stainless steel to form a dense layer of oxide film, this film can resist most chemical corrosion, thus protecting the internal metal from erosion. However, this also makes it difficult to chemically remove the material from the surface of stainless steel during the etching process to achieve the desired pattern or text effect.

Second, the principle of etching itself adds to the difficulty of etching stainless steel. Etching is usually through chemical corrosion or physical etching, forming uneven patterns or text on the metal surface. However, the high surface hardness of stainless steel and chemical stability, making it difficult for the corrosive agent to act effectively on its surface in a short period of time. In addition, the etching process requires control of factors such as etchant concentration, temperature, and time to ensure the etching effect and the integrity of the metal surface. These complex operational requirements make etching stainless steel more difficult.

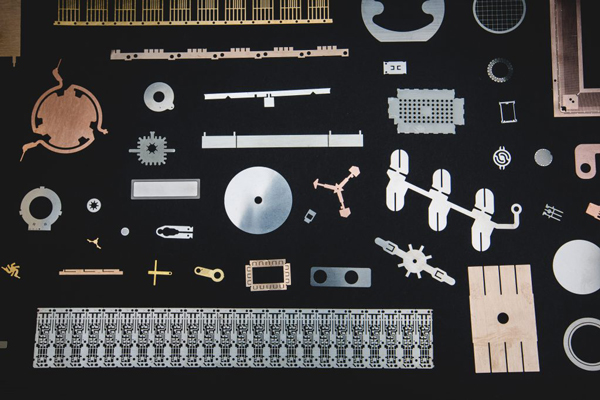

Furthermore, technical difficulty is also an important reason for the difficulty of etching stainless steel. Etching stainless steel requires high-precision equipment and technical support, such as laser etching machines and electrochemical etching machines. These equipments not only require high investment, but also need professional operation and maintenance personnel. In addition, the etching process also requires pre-treatment of stainless steel, such as grinding, polishing, etc., to remove surface oils and oxides to ensure the clarity and consistency of the etching effect. These technical requirements make etching stainless steel more complex and difficult.

Finally, the practical challenges cannot be ignored. During the etching of stainless steel, a variety of problems may be encountered, such as uneven etching depth, pattern distortion, and inconsistent surface roughness. These problems may stem from factors such as the material's own inhomogeneity, lack of equipment precision, or improper operation. Solving these problems requires rich experience and skills, as well as continuous attempts and adjustments. Therefore, the difficulty of etching stainless steel is further highlighted in actual operation.

In summary, etching stainless steel is difficult mainly because the chemical nature and physical structure of stainless steel makes it difficult for the corrosive agent to act effectively on its surface; the requirements of the etching principle itself make the operation complex; the technical difficulties and challenges in actual operation also increase the difficulty of etching. Nevertheless, with the continuous progress of science and technology and the continuous development of etching technology, we have reason to believe that the difficulty of etching stainless steel in the future will be gradually reduced, and more innovations and applications will be realized.

To summarize, the difficulty of etching stainless steel is the result of a combination of factors. In the process of understanding and responding to these challenges, we can not only improve the level of etching technology, but also bring more possibilities for the application of stainless steel.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China