Dry etching technology, as an important microfabrication technology, has a wide range of applications in the fields of microelectronics, optics, biomedicine and precision machinery. Its purpose is mainly to realize the fine processing of the material surface to meet the demand for miniaturization, high precision and high performance in specific fields. In the following, we will discuss in detail the purpose of dry etching and its importance in practical applications.

First of all, one of the main purposes of dry etching is to realize microfabrication of material surfaces. In the field of microelectronics manufacturing, with the continuous improvement of integration, the size and spacing requirements for components on the chip are becoming more and more stringent. Dry etching technology can realize micron or even nanometer-level processing of the material surface through precise control of etching conditions, such as etching gas type, pressure, temperature and etching time, etc., so as to meet the demand for high-precision manufacturing of microelectronic devices.

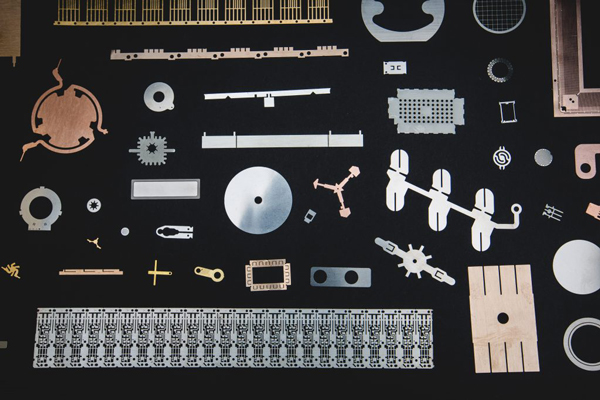

Second, dry etching is also used to create complex geometries and structures. In some applications, it is necessary to create material surfaces with specific shapes and structures to realize specific functions. For example, in the field of optics, grating structures with specific shapes and depths can be fabricated by dry etching for effects such as diffraction, interference and polarization of light. In the biomedical field, dry etching technology can be used to fabricate microfluidic chips and micro-nanodevices such as biosensors, which are used for applications such as cell isolation, culture and detection.

In addition, dry etching technology is highly selective and controllable. Through precise selection of etching conditions and materials, fine processing of different materials can be realized while avoiding damage to surrounding materials. This high degree of selectivity and controllability gives dry etching a unique advantage in the fabrication of complex structures and high-precision devices.

The process of dry etching also enables the cleaning and modification of the material surface. Impurities and contaminants on the surface are removed through etching, improving the cleanliness and purity of the material surface. At the same time, dry etching can also change the physical and chemical properties of the material surface, such as roughness, hydrophilicity, etc., so as to achieve the regulation and optimization of material properties.

In addition, dry etching technology is also characterized by high efficiency. Compared with other processing methods such as wet etching, dry etching usually has a faster processing speed and higher productivity. This gives dry etching a greater advantage in mass production and industrialized applications.

However, it is worth noting that dry etching technology also faces some challenges and limitations. For example, the dry etching process may generate certain thermal effects and mechanical stresses, causing certain damage or deformation to the material. In addition, the cost and maintenance cost of the dry etching equipment are relatively high, and there are certain requirements for the user's technical level and operating experience.

In summary, the main purpose of dry etching is to realize microfabrication of material surfaces, create complex geometries and structures, achieve highly selective and controllable processing, clean and modify material surfaces, and improve processing efficiency. These purposes make dry etching in microelectronics manufacturing, optical, biomedical and precision machinery and other fields have a wide range of applications and important practical value. With the continuous progress of technology and the continuous expansion of application areas, dry etching technology will play a more important role in the future.

The above content on the purpose of dry etching more detailed description, from microfabrication, shape creation, selectivity and controllability, surface cleaning and modification, as well as high efficiency and other aspects of the analysis. Of course, the purpose of dry etching in actual applications may vary depending on the specific needs and scenarios, but in general, it is to fulfill the need for high precision, high efficiency and high quality processing of material surfaces.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China