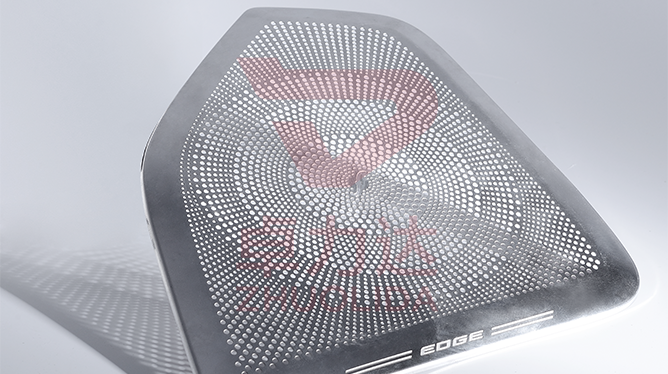

Stainless steel etching processing is a fine process, etched on the surface of stainless steel with a variety of complex patterns and text, these patterns and text are not only beautiful and generous, but also increase the anti-slip, anti-corrosion, waterproof stainless steel products and other functions.

Stainless steel etching processing application areas are very wide, in the field of electronics industry involves lead frame, code disk, a variety of grids, dust nets, smoke alarms, insect nets, etching processing of products in the field of electronics to accelerate the product life cycle is short, a variety of small batches, product accuracy requirements of the tolerance within micron level. Apple, Huawei and other smart phones motor precision core parts used in the processing is also stainless steel etching processing, can ensure product performance, the main production over the cell phone earpiece net, cell phone mid-board, base too components, amplifiers, antennas and micro-antennas and so on. Medical equipment and instrument components in the nickel-titanium alloy, titanium and other metal materials, through the stainless steel etching processing to produce precision implants, stents, pacemaker components, blades, gaskets, chassis parts, and other medical industry, high precision tiny implanted in the human body parts. Stainless steel etching processing for less than 0.1mm wall thickness plate processing has the advantage, which involves the semiconductor field of QFN bracket, EMC bracket, integrated circuit bracket to make the product more fine.

What are the advantages of stainless steel etching processing:

1. Low mold opening cost, short cycle time for template making.

2. No burrs, pressure points, no deformation of the product.

3. Extremely high precision, miniaturization, complex and diversified products can be completed quickly.

4. Can realize the semi-engraving of metal below 0.1mm thickness, suitable for all kinds of metal materials.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China