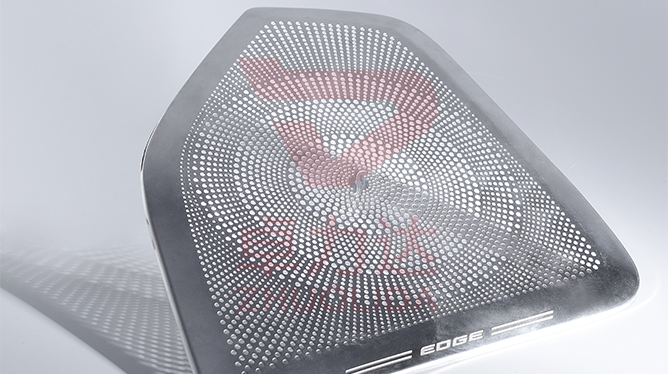

There are many kinds of processing methods for hornets, the traditional processing is stamping process, stamping out the edge of the hornet has a certain burr, ultra-thin point of the product using stamping processing forced processing out of the hornet deformation, and later due to the continuous improvement of the process, in the high-end automotive field is used in the way of etching processing to improve the high degree of precision and to achieve a more stringent tolerance requirements.

The thinner the thickness of the automotive hornet etching process, the hole wall vertical non-curl, no burr, can achieve a minimum aperture 0.1mm, automotive hornet etching material thickness 0.03mm-2mm between the hole spacing can be done to 0.1mm, the depth of the highest precision of up to ± 0.0075mm, the higher the material, the aperture hole diameter needs to be increased, and the hole spacing needs to be widened with it, and conversely, automotive hornet etching Processing, etching solution will corrode off the link fracture, currently using 304, 301, 430, copper and copper alloy and other materials.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China