There are many ways of metal processing in daily life, such as laser processing, linear cutting, stamping, surface treatment, bending process and other processing methods, can be made in metal, plastic, glass and other materials on the production of different text and patterns, widely used in the production of signs, trademarks, patterns and so on. In the face of different processing methods on a lot more confused about what exactly is processed through what process. First of all, we must first judge from the thickness, metal processing thickness of more than 2MM is basically used is stamping, laser processing, stamping processing of these three ways in the mesh processing are commonly used in the traditional process, if only the metal steel or metal plate cutting, that is, selecting the linear cutting and then bending process to form the desired product, in the corrosion resistance, abrasion resistance in the real world scenario, and only the subsequent surface treatment. Consideration of the subsequent surface treatment, such as painting, plating and so on.

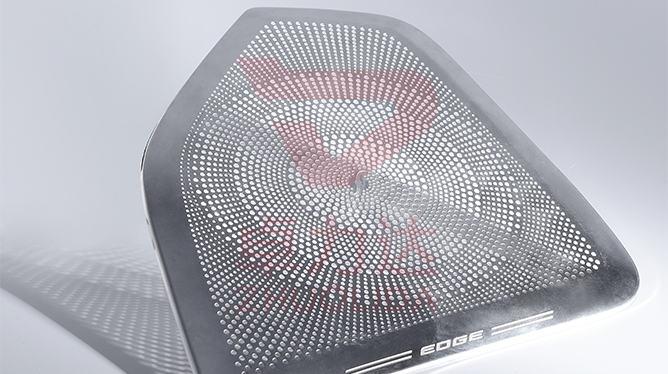

Metal processing materials below 2mm below, in high precision basically using femtosecond laser processing and etching processing, femtosecond laser processing on the surface of the metal will form a burn point, the thinner the thickness of the metal products in the processing will produce deformation, which considers the use of etching, such as touch sensors, camera gaskets, sensors in the encoder code disk, etc. The use of etching processing can realize the components of different graphics and text, which the car horn mesh using the different graphics and text. Text, which is used in the car horn mesh etching processing to increase the aesthetic degree to improve the vehicle's level of protection.

metal etching process common thickness is 0.01MM-2MM between, tolerance up to 0.01MM precision, semiconductor field of 4J42 package board, lead frame, integrated circuit bracket are used in etching process. Etched metal film plate cost is relatively low, metal processing out of the product texture is better, pressure point is not deformed, no scratching and other advantages, to maintain the characteristics of the product, metal etching is commonly used in the production of microporous mesh, miniature gaskets and so on.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China