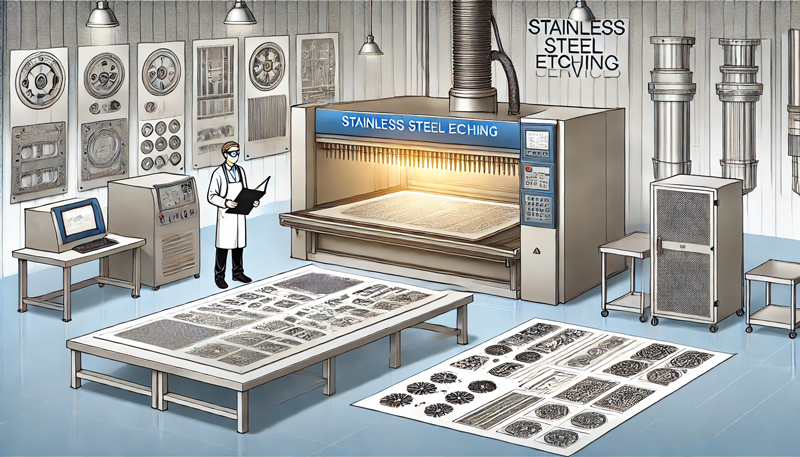

Etching a stainless steel sheet can be done for decorative, industrial, or metallurgical purposes. The process involves selectively removing parts of the surface to create patterns, designs, or reveal microstructural details. Here’s a comprehensive guide:

Chemical Etching (Decorative or Functional Etching)

Electrolytic Etching (DIY or Safer Alternative)

Mechanical Etching (Physical abrasion or engraving)

This is the most common method for etching stainless steel sheets, used for both artistic and functional applications.

Stainless Steel Sheet: Choose the appropriate grade (e.g., 304 or 316).

Etching Solution:

Ferric chloride (for most etching applications).

Hydrochloric acid mixed with hydrogen peroxide (alternative).

Stencil or Mask: Adhesive vinyl, tape, or photoresist film.

Plastic Container: Non-metallic and acid-resistant.

Resist Material: Nail polish, paint, or a specific resist material.

Safety Gear: Gloves, goggles, respirator, and apron.

Prepare the Stainless Steel:

Clean the sheet with isopropyl alcohol or dish soap to remove grease, dirt, or oil.

Dry it thoroughly.

Apply a Design or Mask:

Cover the areas you want to protect using vinyl stickers, tape, or resist material.

Cut the design into the resist (manually or with a craft cutter like Cricut).

Prepare the Etching Solution:

Mix ferric chloride with water (1 part ferric chloride to 2 parts water).

Always add acid to water (not the reverse) to avoid splashing.

Etch the Stainless Steel:

Submerge the sheet in the etching solution, or brush the solution onto the exposed areas.

Monitor the depth of etching (5–20 minutes depending on the depth required).

Agitate the container periodically for an even result.

Rinse and Neutralize:

Remove the sheet from the solution and rinse it under running water.

Neutralize with a baking soda solution to stop the reaction.

Remove the Mask:

Use acetone or a scraper to remove the resist material.

Polish the Surface:

Clean and polish the sheet for a smooth finish.

This safer alternative uses saltwater and electricity to etch stainless steel.

Power Source: 9V battery, phone charger, or DC power supply.

Electrolyte Solution: Saltwater (1 tbsp salt per cup of water).

Mask: Vinyl, tape, or resist material.

Cotton Swab/Sponge: To apply the electrolyte.

Wires and Clips: To connect the power source.

Prepare the Stainless Steel:

Clean the surface thoroughly as in chemical etching.

Apply the Design:

Mask off areas you don’t want etched using resist material.

Set Up the Circuit:

Connect the positive wire to the stainless steel sheet.

Connect the negative wire to a cotton swab or sponge soaked in saltwater.

Etch the Design:

Rub the swab or sponge over the exposed areas.

You’ll notice bubbling as the etching occurs.

Clean and Polish:

Rinse and neutralize the sheet.

Remove the resist and polish.

Decorative Art: Logos, patterns, and personalized designs.

Industrial Use: Nameplates, labels, or functional markings.

Metallurgical Analysis: Revealing microstructures.

Chemical Handling: Work in a ventilated area and wear protective gear.

Electrical Safety: Avoid direct contact with wires during electrolytic etching.

Disposal: Dispose of chemicals responsibly according to local regulations.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China