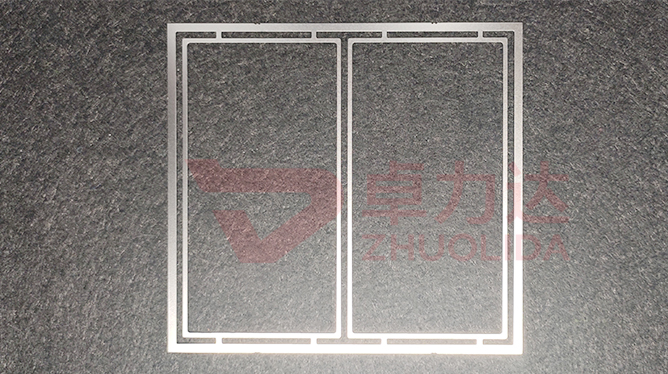

The precision seal ring etching process is a high-precision micromachining technology that is mainly used for precision etching of key components such as manufacturing seal rings. The following is the basic flow of the precision seal ring etching process:

1. Design and preparation

Before starting any manufacturing process, it is first necessary to define the graphics and specifications of the required precision seal ring etching, including length, width, depth, etc.. The design is then carried out using CAD software and the design graphics are converted to G-code for subsequent CNC programming.

2. Material Selection

According to the graphics and specifications to be etched, select appropriate materials, such as stainless steel, titanium alloy, engineering plastics and so on. At the same time, consider factors such as cost, processing difficulty and performance requirements.

3.Workpiece fixing

Fix the selected material on the precision seal ring etching machine to ensure the accuracy and stability of the workpiece position. Usually use vacuum fixture or mechanical fixture for fixing.

4. Chemical decontamination

Prior to precision sealing ring etching, the surface of the workpiece needs to be chemically decontaminated to remove grease, dirt and other impurities. This can improve the etching effect and extend the service life of the workpiece.

5. Dry etching

Selected gases (e.g. CF4, O2, Ar, etc.) are introduced into the etching machine and plasma is formed under the action of a high-frequency electric field. These plasmas react with the material on the surface of the workpiece, gradually removing the material and realizing the etching process. Dry etching has the advantages of high precision, high speed and low pollution.

6. Reaction stop and workpiece removal

When the etching reaches a predetermined depth, stop the introduction of etching gas, while stopping the role of high-frequency electric field. Then remove the workpiece to end the precision seal ring etching process.

7. Post-processing

After the etching of precision sealing ring is completed, the workpiece is subjected to post-processing work such as cleaning, drying and inspection. Among them, the cleaning process mainly removes the residues and pollutants on the surface; drying is to ensure that the workpiece is dry and prevent rust; inspection is to detect and control the etching quality and precision to ensure that the workpiece meets the requirements.

8.Delivery and use

After post-processing, the workpieces are packaged and transported to the end users. According to different applications and needs, the etching process of precision seal ring may be slightly different. However, the above process can be used as a basic reference to help understand the general and critical steps of the process. With the development and advancement of technology, the precision sealing ring etching process will continue to be optimized and improved to provide more support for the progress of the manufacturing industry.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China