Etching stainless steel can be done using various methods, depending on the desired outcome and available materials. Here are a few common techniques:

Materials Needed: Ferric chloride solution or a mixture of hydrochloric acid and hydrogen peroxide.

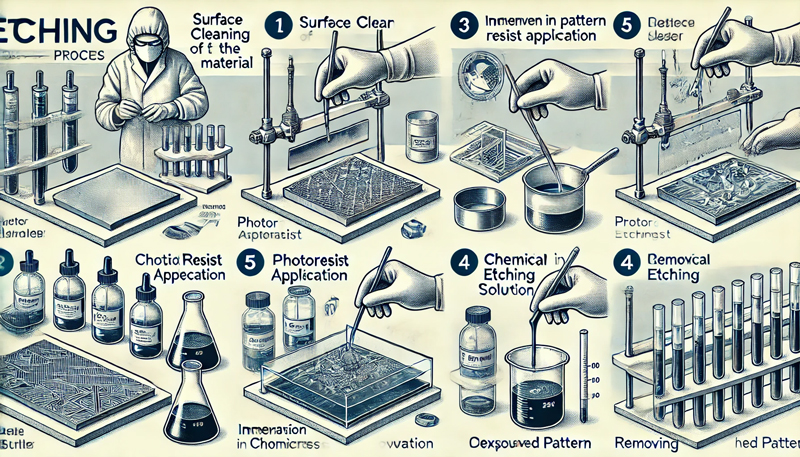

Process:

Clean the stainless steel surface thoroughly to remove oils and dirt.

Apply a resist (like vinyl or a special etching cream) to areas you want to protect.

Submerge or brush the metal with the etching solution.

Rinse off the solution and remove the resist.

Materials Needed: A laser etching machine.

Process:

Design your pattern or text using graphic software.

Set up the laser machine and adjust the settings based on the thickness and type of stainless steel.

Place the stainless steel piece in the machine and run the program to etch your design.

Materials Needed: Power supply, electrolyte solution (like sodium nitrate), and a stencil.

Process:

Create a stencil with your design.

Connect the stainless steel to the power supply as the anode.

Immerse it in the electrolyte solution and apply the current, which will etch the exposed areas.

Always wear appropriate safety gear, such as gloves and goggles.

Work in a well-ventilated area, especially when using chemicals.

Personalization of items (like jewelry or tools).

Creating decorative patterns for artistic projects.

Industrial applications for labeling or identification.

Choose the method that best suits your project requirements and available tools!

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China