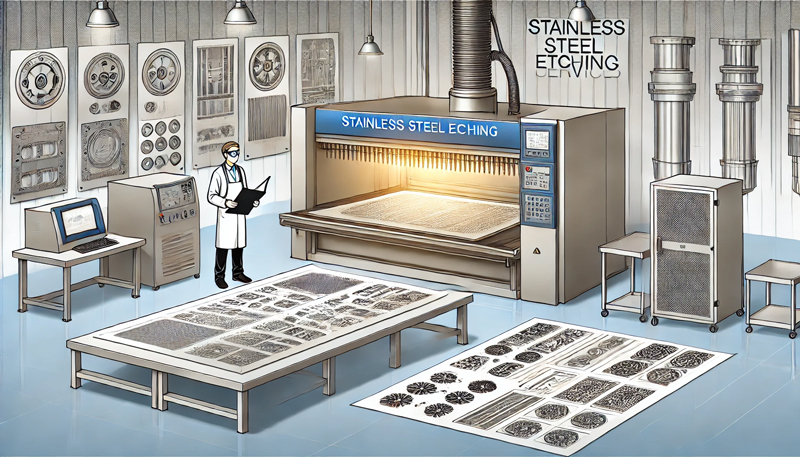

metal etching stainless steel is a technique used to create designs, patterns, or markings on the surface of the metal. Here are some common methods for etching stainless steel:

Process: This method involves applying a resist material to the stainless steel surface, followed by immersing the metal in a chemical etchant (like ferric chloride or nitric acid). The areas not covered by the resist will be etched away.

Materials Needed: Resist (like vinyl, tape, or a photoresist), etching solution, protective gear.

Process: This technique uses an electrolytic solution and an electrical current to etch the stainless steel. A stencil or resist is applied, and the current causes the metal to dissolve in the exposed areas.

Materials Needed: Electrolytic solution (often saltwater or a specialized solution), power supply, stencil.

Process: A laser engraver can be used to etch designs onto stainless steel. The laser removes material through intense heat, allowing for intricate designs and high precision.

Materials Needed: Laser engraving machine.

Process: This involves blasting the stainless steel surface with abrasive materials to create a frosted effect or to remove a layer of the metal. It can be used to create patterns or text.

Materials Needed: Sandblasting equipment, protective gear.

Process: This is done by physically carving or scratching the surface using tools like engraving machines or CNC routers. It's suitable for detailed designs and lettering.

Materials Needed: Engraving tools or CNC equipment.

Always wear protective gear, including gloves, goggles, and masks, especially when working with chemicals or high-powered tools.

Ensure good ventilation if working with chemicals or fumes.

Test your etching method on a scrap piece of stainless steel first to refine your technique.

Adjust the exposure time or etching solution concentration based on the desired depth and detail of the etching.

These methods can be used for a variety of applications, including jewelry making, signage, and decorative pieces. If you have a specific project in mind, let me know, and I can provide more tailored advice!

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China