Etching stainless steel is a technique commonly used for adding intricate designs, logos, or labels to metal surfaces, and there are a few different methods you can use depending on the tools and materials you have. Here are the most common approaches:

This is the most popular and precise method for Stainless steel etching, often used for industrial or artistic purposes.

Stainless steel piece

Stencil or resist material (vinyl sticker, tape, or photoresist film)

Ferric chloride solution or hydrochloric acid (etching agent)

Rubber gloves, goggles, and a mask (for safety)

Plastic or glass container (avoid metal containers)

Rubbing alcohol

Cotton swabs or paintbrush

Running water for rinsing

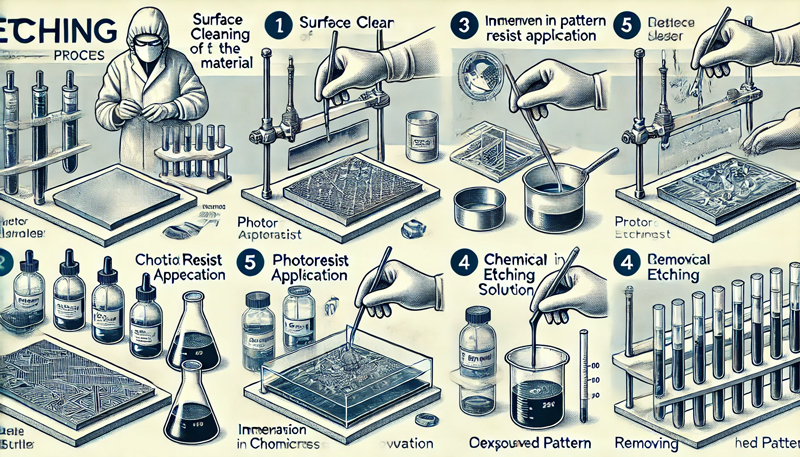

Prepare the Surface: Clean the stainless steel with rubbing alcohol to remove oils or dirt. This ensures the etchant only affects the intended area.

Apply the Resist: Use a stencil or resist material to mask off the areas you don’t want to etch. Vinyl stickers are great for this, but tape or photoresist film also work well. Smooth out any bubbles in the resist.

Apply the Etchant: Place the stainless steel in a container and cover the exposed areas with the etching solution. Be careful to handle chemicals with gloves and in a well-ventilated area.

Wait for the Etching: Allow the solution to work on the surface for 10–30 minutes, depending on how deep you want the etch. Check periodically for depth.

Rinse and Neutralize: Once the desired depth is achieved, remove the metal and rinse it thoroughly with water to stop the etching process. Remove the resist and clean the surface.

This method uses an electrical current to etch the metal. It’s a cleaner, safer method compared to chemical etching and works well for detailed designs.

Stainless steel piece

Stencil or resist material

Saltwater solution (distilled water with salt)

Power supply (DC power source like a 12V battery or an AC adapter)

Cotton swab or felt pad

Alligator clips

Rubber gloves and goggles

Prepare the Surface and Resist: Clean the metal, and apply the stencil or resist just like in chemical etching.

Prepare the Electrolyte: Dissolve salt in distilled water to create the electrolyte solution.

Set Up the Power Source: Attach one end of the power supply (negative lead) to the stainless steel piece.

Start Etching: Dip the cotton swab or felt pad in the saltwater, and attach the positive lead to it. Carefully rub the exposed metal areas with the soaked swab to etch the design. You should see the metal darken as it etches.

Check and Clean: Once the etch depth is satisfactory, clean the metal with water and remove the resist.

This is a high-tech option often used in industrial settings, where a laser engraver is used to vaporize the surface layer, creating a high-contrast mark. This method is very precise but requires access to a laser etching machine.

Always work in a well-ventilated area, especially when using chemicals, and wear protective gear such as gloves, goggles, and a mask. Chemical etching agents are hazardous, so handle them carefully and follow proper disposal guidelines.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China