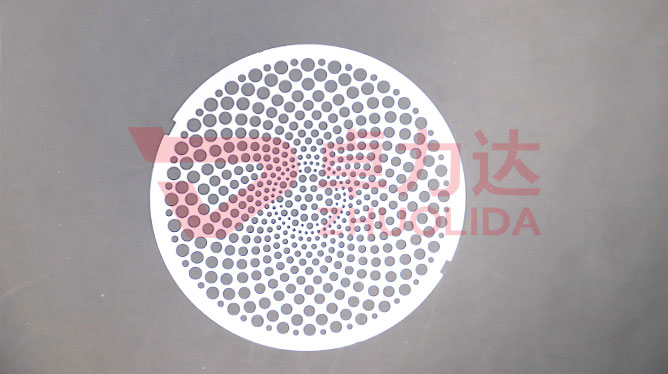

Etching technology is a common metal processing method, widely used in various industries. In the process of blower screen processing, the control of etching process is of great significance for the quality and usability of the product. In this paper, we will introduce the etching process of blower screen in detail and discuss how to control its accuracy.

Blower screen etching process

1. Pre-treatment: The blower screen is cleaned, de-oiled and other treatments to ensure that the surface is clean, so as to facilitate the subsequent etching process.

2. Laminating: Place the screen on the adhesive film to make sure the position is accurate in order to avoid etching errors.

3. Exposure: Through ultraviolet irradiation, make the adhesive film and the blower screen closely fit to prevent etching liquid penetration.

4. Etching: Put the blower screen and the adhesive film together into the etching machine for etching treatment.

5. Remove the film: remove the adhesive film to get the etched screen.

6. Post-processing: cleaning, drying and other processing of the blower screen to remove residues and improve the surface quality.

Blower screen precision control methods

1. Equipment precision: choose high-precision etching equipment and auxiliary tools, such as high-precision exposure machine, etching liquid circulation system, etc., to ensure that the performance of the equipment to meet the processing requirements.

2. Mold precision: Make high-precision molds and control the size and shape errors of the molds to ensure the accuracy of the size of the blower screen.

3. Operation precision: Strictly control the operation process to ensure the accuracy of each operation step. For example, in the process of laminating the film, to ensure that the adhesive film and the blower screen are completely adhered to; in the exposure process, to control the time and intensity of UV irradiation and so on.

4. Temperature and time control: control the temperature of the etching solution and etching time to avoid over-etching or under-etching. By constantly adjusting the temperature and time parameters to find the best etching process parameters.

5. Chemical reagent control: Choose high-quality chemical reagents, and regularly test the concentration of etching solution and pH and other indicators to ensure the stability and accuracy of the etching process.

6. Personnel training: professional training for operators to improve their skill level and operational proficiency to ensure that they can accurately implement the etching process.

7. Quality inspection: quality inspection during and after the etching process, such as using microscope to observe the surface roughness of the screen, size inspection, etc., timely detection and correction of quality problems.

Hair dryer screen etching processing is a delicate work, requires a variety of precision control measures. By choosing high-precision equipment and tools, making high-precision molds, strictly controlling the operation process, reasonably adjusting the temperature and time parameters, choosing high-quality chemical reagents, professional training for operators and strengthening quality inspection and other measures, the precision and quality of the etching process of the blower screen can be effectively improved.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China