There are several reasons for stainless steel funnel filter sheet etching processing:

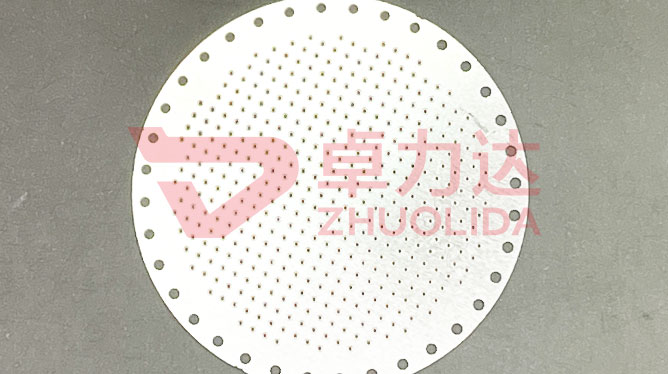

1. Increase filtration efficiency: stainless steel funnel filter sheet etching processing can precisely manufacture tiny holes and slits, and these tiny structures can effectively filter and capture tiny particles in the liquid. This precise manufacturing method can improve the filtration efficiency and ensure the purity of the liquid.

2. Increase the filtration area: through the etching process of stainless steel funnel filters, many tiny grooves and holes can be made in the stainless steel funnel filters, thus greatly increasing the filtration area. This not only improves the filtration efficiency, but also reduces the thickness of the filter, making it more lightweight and easy to carry.

3. Increase corrosion resistance: stainless steel itself is a corrosion-resistant material, but after the stainless steel funnel filter etching process, a dense oxide film can be formed on the surface, further enhancing its corrosion resistance. This makes the stainless steel funnel filter can be used in a variety of corrosive environments, but not easily damaged.

4. Improve filtration accuracy: Stainless steel funnel filter etching process can create tiny holes and gaps, which can achieve high precision filtration. This precise manufacturing method ensures that only specific particles can pass through the filter, while other sized particles will be intercepted. This makes stainless steel funnel filter sheets ideal for certain high-precision filtration applications.

5. Easy to clean: Because the tiny holes and crevices formed by the etching process of stainless steel funnel filters are regular, they can be easily cleaned during use. This makes the stainless steel funnel filter more suitable for applications that require frequent cleaning.

6. Increase service life: etching process can significantly improve the service life of stainless steel funnel filter. This is because the etching process forms tiny holes and gaps with high wear resistance and pressure resistance. In high temperature, high pressure or corrosive environments, these tiny structures can effectively protect the filter sheet from damage, thus extending its service life.

7. Reduced maintenance costs: As etching can improve the service life of stainless steel funnel filters, it can reduce the frequency and cost of replacing filters. In addition, because the etching process can improve the filtration accuracy and efficiency, so it can reduce the amount of liquid that needs to be processed, thus reducing the processing cost.

In conclusion, the etching process of the stainless steel funnel filter sheet etching process has many advantages, such as increased filtration efficiency, increased filtration area, increased corrosion resistance, improved filtration accuracy, easy to clean, increased service life and reduced maintenance costs. These advantages make the etching process of stainless steel funnel filters are widely used in many fields.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China