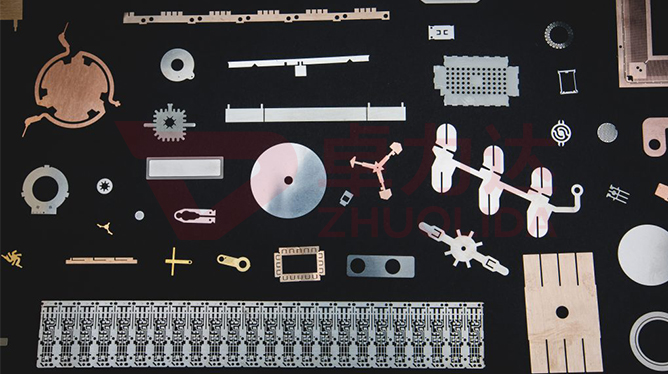

Stainless steel slit sheet etching is a precision fabrication technique widely used in microelectronics, biomedical and optical applications. This technique utilizes a chemical reaction to etch stainless steel slit sheets to create precise shapes and sizes.

First, the principle of stainless steel slit sheet etching processing

The principle of stainless steel slit sheet etching processing is to use chemical reaction to remove part of the material on the metal surface. In the etching process, chemical reagents and stainless steel slit sheet surface chemical reaction, producing soluble compounds, so as to remove the material on the surface of the slit sheet. This chemical reaction is highly selective and allows precise control of the depth and shape of the etching.

Second, the steps of stainless steel slit sheet etching processing

1. Preparation of materials: select the appropriate stainless steel material and prepare it into the required shape and size.

2. Surface treatment: remove grease and pollutants on the surface of stainless steel to improve the penetration and adhesion of etchant.

3. Apply etchant: Apply etchant to the surface of the stainless steel slit piece to create a chemical reaction.

4. Etching process: Put the stainless steel slit piece coated with etchant into etching machine for etching process.

5. Cleaning and processing: Remove the etchant remaining on the surface of the slit piece, and carry out the necessary processing, such as polishing, coating and so on.

Third, the characteristics of stainless steel slit piece etching processing

1. High precision: stainless steel slit sheet etching processing can precisely control the depth and shape of the etching, to achieve high precision manufacturing.

2. High efficiency: etching processing can complete a large area of etching in a short period of time to improve production efficiency.

3. Strong applicability: this technology can be applied to different materials and shapes of stainless steel slit sheet, a wide range of applications.

4. Environmental protection: the chemical reagents used in the etching process can be effectively controlled and processed to reduce the impact on the environment.

Fourth, the application of stainless steel slit sheet etching processing

1. Microelectronics field: stainless steel slit sheet etching processing can be used to manufacture microelectronic devices and circuit boards.

2. Biomedical field: it can be used to manufacture precision parts in biomedical equipment, such as microfluidic chips and biosensors.

3. Optical field: can be used to manufacture optical components, such as lenses and reflectors.

In short, stainless steel slit sheet etching processing is a high-precision, high-efficiency, applicable and environmentally friendly manufacturing technology, widely used in various fields. With the continuous development of science and technology, this technology will continue to be improved and perfected, injecting new vitality into the future manufacturing industry.

Contact: andy_Lai

Phone: 18938693450

E-mail: yw9@zldsmt.com

Add: Building A3, Huafa Industrial Park, Fuyong Town, Fuyuan Road, Fuyong Town, Baoan District, Shenzhen,China